You have never noticed, driving around your neighborhood, how much are unfinished and already as abandoned brick boxes of houses, cottages with gaping windows of windows? Apparently, considerable money is invested in such a number of bricks, concrete, digging of pita and other construction. In essence, most of this money buried to the ground, thrown into the wind. After all, these unfinished houses and cottages are selling at a price much less invested in their construction. And if you look at some built in the recent past of the house or cottages, it is unlikely that you will find among them not that the architectural masterpiece is just a house with its architecture that caused at least respect, and unfortunately. Probably Russia is still the richest country in the world, since we allow yourself so unwise to spend money.

Where does this waste come from? Why do we have accustomed to invest in the construction of ruins or in some awkward buildings?

First of all, from the fact that a private developer cannot often calculate their real opportunities and usually wakes up for the construction of a house or a large cottage than he can alter, bring to mind and subsequently serve.

It happens that a person who built a four-storey house or cottage, as a rule, lives on the same floor, and goes on a tour, but on these floors of the cottage you need to clean the windows, to wash them finally. The cost of construction, exploitation of such a house or cottage is very high. To make money to fly to the wind, it is necessary to act on the principle of reasonable sufficiency.

Starting the construction of the house, the cottage Private customers often treated themselves to the thought that they would be able to find some wonderful, almost darm builders, cheap, but talented architects. As a rule, all these dreams in the process of building a cottage are no more than illusion. And the economy begins. But save not on what it would be necessary. As a result, it turns out that it will cost to correct the work of these miracle builders, it will cost even more expensive than initially finding no normal designers and listen to their recommendations for choosing a contractor for the construction of the house.

I would like to warn potential customers from the architects who swear in a couple of weeks to design the house of your dreams. Already during the construction of a house or cottage, this approach to the case can get sideways, not to mention whether you can live in this dream. After all, if you want to start building a house in the summer, it is better to apply to the architect in the fall.

The practice of building houses, cottages shows that the more attention is paid to the project, the smaller financial costs are waiting for you at the construction stage. It is better to design a house once than rebuilding more than seven times, "the experience suggests.

In order for your presentation of the future house to be the most complete, you should order an architect layout at home with the surrounding area. Many customers believe that the cottage layout is needed to stretch more money from him (customer). This is rooted incorrectly. The layout of the cottage will help save your money and nerves, because you will present your future house, and the result will not be unexpected for you. A cottage layout made on a 1: 100 scale - gives a fairly complete concept about the object, but on the scale of 1:50 it will be possible to show all the architectural features of the house and the various types of finishes so that it will allow you to literally shovel with your unfresphenny house. Photo of house layouts You can look at our page.

It is necessary to make geological surveys on the site and geodesic shooting of the relief of the site - they are necessary as the source data for the design of the cottage foundation. The foundation is the basis of the house and the foundation problems can lead to the dissent of the entire structure. Most of the houses abandoned at the construction stage and abandoned that they have problems with the foundation. Either due to the uneven sediment of the foundation, or due to the force of frosty powders of the soils of the bone foundation. Cracks can go on the walls of the house, so it will be easier to order geological surveys than grieving then over your thinned and cracked home.

Also, in order to save it, it is better not to plunge the ground floor to the ground - you will save on earthworks, the material of the foundation and waterproofing. Another thing, if you want with the minimum building area to get a maximum useful Square - Here, without the basement, you can not do, usually there are pools, gyms, storerooms - everything that did not fit on other floors.

To achieve a tangible savings in the construction, considerable attention should be paid to the selection of building materials. The most progressive wall material for country house It is aerated concrete, stacked on a special adhesive solution. Modern aerated concrete blockmanufactured by german technology, with a thickness of 375 mm completely satisfy the standards for heat engineering. The wall is very smooth, because the seams between the blocks are not more than 2 mm, and does not shrink. Therefore, after a minor preparation of the surface of the wall, it is possible to start its final finish. In general, the cost of material and installation aerated concrete wall Twice cheaper brick and at the same time three times warmly. One of the advantages of the walls from the aerated concrete is also that it is vapor permanent, it allows you to breathe such walls, getting rid of excess water vapor inside the house.

But it should be remembered that the carrying capacity of the aerated concrete is low, although it is enough to carry reinforced concrete overlaps of two or three floors. Also, aerated concrete absorbs moisture well, so it should be protected by its surface from its impact.

To finish facades, vinyl siding is the most economical material. He is attached to the crate, leaving the air gap, which allows you to ventilate the outer surface of the aerated concrete, removing excessive moisture from it.

Siding does not need to be painted, it is not subject to rotting, to maintain the appearance, it is enough to wash it from time to time. Siding finishing can be combined with other, more expensive finishes, for example, decorative synthetic plaster with various fillers: quartz, marble, granite crumbs of various fractions, it is important that the plaster is moisture resistant and vapor-permeable.

The solidity of your home will undoubtedly add cladding with bricks, for savings you can use the products of domestic plants. The use of these materials in harmonious proportions will give the facades of your home unique, individual appearance.

Sufficiently inexpensive roofingwhich can be used - bituminous tile, but to give the house of a more representative species, you can apply a domestic polymerpessage tile. It has the same sizes as the Finnish ceramic or cement tile, but it has two times less weight with a much lower price, does not ourselves when falling. The disadvantage of ceramic, cement substance, polymer-sand tile relative to the bituminous - relatively large weight, which entails an increased consumption of material on stropile structures. But the bituminous tile will be in disrepair faster, the traditional tile is tested for centuries and is undoubtedly more durable.

Metal-plastic windows are the most optimal option for a person who can count money. W. metal plastic windows The same advantages as vinyl siding - They do not need to repaint them over time and they cannot be rotting. In our climate, you must install two-chamber double-glazed windows. Better if the windows have a triple contour seal and high-quality shut-off fittings tightly pressing window sash to the frame. At the same time, it is necessary to remember that it is better to contact the company that gives a multi-year warranty on its windows, because some problems with windows can manifest itself in the year of operation and in two years. Excessive savings on the windows may subsequently lead to unjustified costs.

A well-known planning and constructive solution is playing a large role in the cost savings. Maximum thread of the construction of the house, we reduce the number of necessary operations during installation, the amount of required material - the labor costs and costs will decrease accordingly.

As you know, the plane that flies well and looks beautiful too. Beauty is derived from its functionality. So a good house does not require anything superfluous. After all, the house may have a spectacular appearance Not at the expense of architectural excesses such as turrets and columns, but due to thoughtful proportions, combinations different species Finishes, interesting color solving And at the same time be simple from a constructive point of view. Moreover, we already live in the twenty-first century and classic columns and stucco parts on the facades look at the new buildings at least strange. Modern architecture is not focused on the details, but operates with color, plane, volume, texture ....

An important role in saving money is played by both the heating system you will stop. Either it will be a traditional radiator system which at the initial stage will be undoubtedly cheaper, or the heating system across the floor. The advantage of the heating system across the floor is that water here is not necessary to heat up to discharge temperatures, because the area of \u200b\u200bheat-return in this case is more, as a result, 15-20% of the means saves compared with the radiator system. In addition, when heating through the floor, the air rises to a smaller height and dust in the house will be significantly less. Also, the refusal of radiators will give the opportunity to more freely separate the furniture, which is important if the area of \u200b\u200bthe premises is small and on the account every square centimeter.

What is the recipe for the construction of a good house? First, it makes a reasonable proportion to find a reasonable proportion in their ratio. Secondly, we suspend the choice of builders, you will definitely look at the houses built for them, operated for several seasons. Thirdly, do not refer to the designers who per week on the computer will be depicted, it is not a computer! When the architect suggests you options for planning Try to imagine them in reality, think - everything is convenient in the layout. (The case towards the case when you ordered ready project by catalog). Fourth, if you have already decided on the designers, negotiate with them and on the manufacture of a layout of the house and on the design of interior design, listen to the recommendations of the architect on the choice of stronel. Fifthly decide on the materials of which will be built a house, or it will be expensive, durable materials, or less expensive and less durable - the choice of materials depends on what future the house is being built, as soon as you want to settle in it. Simply put, if you want to build for yourself and your family, a beautiful, comfortable home and not to fly "into the pipe" you need to approach this case seriously and weighted.

Based on the foregoing, it is possible to formulate a collective image of a good economical housewhich, in our opinion, will be acceptable at a cost for a fairly wide range of families who want to live in their own home.

By area, such a house corresponds to a decent urban apartment - 150 m2. On the first floor: living room - 28 m2, kitchen - 12 m2, entrance hall, bathroom, pantry, boiler room, in mansard floor: 3 bedrooms - 20, 16 and 11 m2, as well as two bathrooms. All this - as it were, a residential module to which will then be able to attach a garage, a terrace, a veranda, additional living quarters. The cost of such a residential building will be lower than the cost of a similar urban apartment and at the same time be able to develop. In the plan, the house represents a square with sides of 9.4 m. This feature of the project makes it possible to save a little on wall material And on heating, since the square perimeter is less than the rectangle of the same area.

Walls are made of aerated concrete. The lack of a middle carrier wall gives savings on the foundation under this wall and on the wall itself and also makes it possible to easier to redecessing if it is necessary. Wall decoration outside - siding and decorative plaster. Roof - bituminous tile. This project may come for the second guest House On your site and for typical building village.

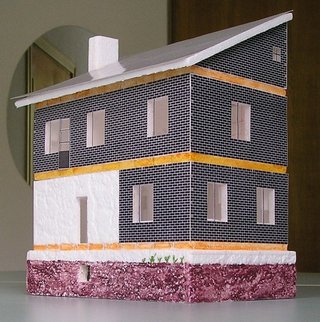

I wanted to imagine clearly how the future house would look. For this reason, this common drawing was born.

The result was absolutely not impressed, by that really wanted to consider the house from all sides. Then the search for ideas began to create a layout. Remember in the former children's times Mastered from cardboard and paper of soldiers, but when trying to build at least part of the foundation from these materials it became clear that it is much easier to build real housethan his layout. Without thinking, bought a foam that the ceiling is placed to give a divine species. (Unfortunately, a flat foam from two sides was failed to find, so I took that more than more than flowers, petals, and with the texture by the type "loose plaster".) This material It approached as it is impossible by the way. Firstly, it has a thickness of 0.5 cm, which almost corresponds in proportion to the thickness of the present wall, and secondly, the foam is very easily and quickly processed - it can be chopped into smooth pieces of a conventional knife. PVA used as glue.

To make a layout at home, you need to know exactly what you do. That is, you need to have a drawing of a house, a sketch or a plan with basic sizes.

I had enough draft architect's sketch, which was at hand at hand. After catching the size, I decided to take a scale as a proportion of 1 m \u003d 2 cm. This proportion is easy to count, and the size of the layout is good - the layout of the house is not large and not small, the wall thickness is almost proportional. And then a lot of routine work - the markup of the foam, cutting the foundation, walls, roofs, gluing pieces together.

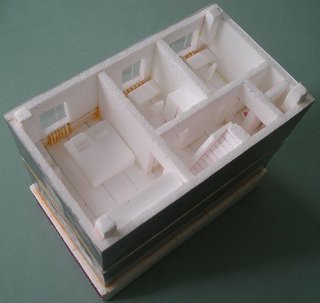

Entrance door The house is visible on a white background. Ask why there are no steps?! How to climb the house?! There will be steps! And there will be a corridor, just in the place where the wall is white. See below. Mock at home I needed necessarily folding so that you could see the inner location of the rooms, stairs and furniture. For this reason, I did not glue the second floor, but made it removable. That looks like interior arrangement at home.

Honestly, the staircase I was too lazy to make a completely proportional - one step layout is equal to two real. As they say, the next time :-). But otherwise everything is correct - the slope occupied size, width. The staircase closes bearing wall From the brick that is needed in order for it to rest over the slabs of overlapping the second floor.

At the layout you can clearly appreciate the spread of light in the bright time of the day. Just need to know, in which direction to the north will stand the house.

On the mockup of the first floor it is visible as a staircase on the second floor. Visible descent to the basement. Yellow stripes under the windows indicated heating radiators. Bath and toilet are visible "naked eye." Green The heating boiler is indicated. Ventilation niche passes the toilet. And also visible to the basement. In principle, the descent to the basement would be logical to place under the stairs, but these are questions to architects. The entrance door to the house is near the sofa. When entering the house, on the one hand there is a bathroom, a toilet and Camorka. On the other hand the kitchen. The room on the first floor is quite spacious, so any redevelopment is possible - you can separate, for example, a cuisine by partition, or hide the inputs in the bathroom and toilet. The sofa can be put in the stairs, and the kitchen is separated by a bar counter. An option without partitions or with sliding partitions is preferable if you are going to get parties and crowded gatherings - then you need a lot of space.

Orange color marked plates of overlaps. Naturally, they will be hidden under the masonry brick, but for clarity of the layout, I brought them out.

On the second floor there is one large bedroom and two small children's rooms. As well as shower and toilet. Also visible the staircase in the attic and access to the balcony in one of the children's rooms.

In this picture, two children's rooms are better visible, as well as inlets into rooms. Under the windows are radiators of heating. Unfortunately, the ladder of lifting from the first floor is not visible in the picture on the second - it closes the staircase on the attic. You need to see the layout of the house live!

Now we make the roof of the house and have it over the second floor.

The roof of the house I made a single one, as the house will border the deaf wall with the neighbors, although the duplex would look much more beautiful.

The layout of the house is almost ready! The smallest thing remained - to attach the corridor. The corridor can be built and not immediately, but as finances appeared for construction

The corridor can make any value - it all depends on your taste. The roof of the corridor is at the same time a balcony where you can spend the laundry for drying or install a hammock. If desired, the balcony can be glazed or just install a plastic transparent visor from rain.

A portion of the balcony enters the deaf wall. There you can hide to tired parents and smoke so that the children see.

Last barcode - garage. Fucked as finance arrives. From the garage you can immediately go to the corridor through the inner door. If someone seems a balcony too small, then it can be done above the roof of the garage. The garage and the corridor build on a light foundation, as the weight of these buildings is insignificant.

From materials you need the following: a foam of 0.5 cm thick, PVA glue, paper, tape. Tools: blade or sharp knife for cutting foam, scissors, handle for applying markings on foam, pencils, line.

"Outdoor finish" in the form of bricks did on the printer, followed by "lamination" - pasted Scotch. Not grateful this is a matter, because just that, the tape is crookedly glued and the workpiece must be thrown away. For the future I want to try on the present laminate. Without lamination, it will not be possible to paste the texture to the house, since the paper swells from glue. But if nevertheless succeeds to glue, the paper is very quickly hidden and the layout of the house will lose its beautiful shiny look.

My brick is black - there was no color printer at hand. Now it is not a problem and you can make a "finish" for any material. And the special fans can stick wallpaper and make parquet. But I am pass. Ungrateful this thing.

Here, actually, and that's it!

How to make an architectural layout of paper with your own hands.

In this lesson, it is enough in detail how you can make an architectural layout from simple materials at home. We decided to show you ways to work with paper and methods for its transformation into bulk forms on the example of the architectural layout of the business center with a plurality of complex elements and cuts.

Materials: Dense toned paper, self-adhesive film, double-sided scotch, PVA glue, children's colored paper, cuttings from the brushes (for the spire).

Instruments: Scissors, metal rules of different sizes, a paper knife, a circulation and several tools that I forgot :-).

Phased creation of a building layout.

Part 01. Sequential execution of structural elements of walls.

1. COLOR FLOOR.

In order to show the thickness of the wall to window Rama It is necessary to install ribs.

The glass of the outer part of the window is simulated using authonic. Toning is pasted on double-sided adhesion, slightly larger.

2. First floor.

The first and subsequent floors of all walls of the building are performed according to a similar scheme as the ground floor.

All decorative elements are manufactured by gluing the details of the jack, which reduces the error in size.

3. Floors from the second fourth.

4. Fifth floor.

Part 02. Compound of structural elements of walls in the block.

1. Wall No. 1.

2. Wall No. 2.

3. Wall No. 3.

This wall is a bit more complicated than previous ones.

4. Wall No. 4.

Part 0 3. Sequential execution of frontal cuts of the layout.

1. Cut No. 1.

Because The layout of the building is partially executed, it is necessary to make cuts. One of them will be detailed, and the other will indicate only the basic elements of the design in the section of the cut.

2. Cut No. 2.

In contrast to the drawing on the section of the layout, the internal elements of the structure (windows, doors hidden from the wall cut area and partitions are visible, which makes it more accessible to perception.

Actually, for simplicity with gray, it is designated that it falls into the cut area in the drawing.

Part 04. Connection of frontal cuts with walls of the building.

1. Section No. 2 with walls No. 1 and No. 2.

2. Section No. 1 with walls No. 3 and No. 4.

Part 05. Sequential execution of collection and collapsible elements of the layout.

1. Dynamic structural unit number 1.

Under the dynamic structural unit, the moving part of the layout is meant, which is essentially a complex cut.

2. Dynamic Structural Block No. 2.

Both dynamic elements are fixed in the layout by means of magnets.

Part 06. Installing the layout blocks to the stand.

The stand is made of plywood.

Part 07. Phased performance of the central entrance.

Part 08. Phased fulfillment of the facade part of the layout of the building (tower).

Part 09. Sequential horizontal cut (fifth floor).

Part 10. Sequential execution of the dynamic structural unit (roof).

Part 11. General form Layout with exterior.

Many people seeing beautiful and neat buildings made by architects, dream to learn how to create the same reduced copies beautiful houses. Learning to do real complex layouts is not easy, but in your power and opportunities to collect a decorative layout of the house on a scale of 1:50, in advance drawn the contours of the details and facades at home, as well as roofs and frames.

Instruction

1 Decoming layout you will need a plywood with a thickness of 6-8 mm, as well as materials for facades, partitions and roofs. From plywood, make a frame of the house and place it on a flat surface.

2 Differently prepare the facades cut out according to the drawings, and shift door and window openings in them. Then put the locations of the sections and joints.

The 3-fence of the house make out of wide rails by sticking them to the finished box at home, and also separately make a porch with stairs from solid wood bars.

4 The 4th of thin plywood separately cut the doors and window platbands, stick to their sandpaper, take the contour with thin rails and tightly glue to the frame of the house in the openings. In the windows instead of glass, insert a plexiglass of millimeter thickness with plastic or wood frames glued on the outside.

Stress a separate sheet of plywood and drink double roof For a house, and then roofs for individual buildings, if you want to complement the house in the yard. Square from thin tin drainage pipes And the gutter, and then fasten them on the roof rods. Chimnery Make from small wood bars.

6After the small details will be ready, start collecting the house. First, collect the box at home, then place the roof on it, then fasten the roofing doors.

7 Pull separate beautiful columns or rails that you close the joints of the plywood sheets so that the house looks more beautiful. The surface of the building is cast, cover the mourn and varnish or paint paint.

8 Note the manufacture of buildings layouts with simple models - for example, small huts or barns. Then you can improve your skills and move to the construction of more complex layouts.

Mock at home and his architectural model - what do they differ? The first can be made of available materials: paper, cardboard or wood. It does not have to repeat the form of a certain structure. The architecture of the construction can be any you like, if only the result of your creativity also liked you, and others.

The architectural model is an exact copy of any building with the repetition of all major and secondary signs. It is built from expensive materials, and its creation can take several months of hard work. Therefore, we offer to begin to build a layout of the houses from the girlfriend. Do not know how? In this article you will find recommendations and detailed instructions How to make cardboard and wood layout.

The layout of the paper house, the scheme of which is attached in this article, is a simple building, although work on its creation can become an interesting creative process requiring attention and doctrine. Paper will need dense, newspaper or packaging will not fit.

Better to take standard sheet 29x21 cm. In the event that the contours of your future house do not fit into the size of the sheet, you can glue two by the "joint in the joint" method with an overlay strip of a 2 centimeter width. After the workpiece of the desired size is obtained, it is necessary to make markup. We offer to build a layout of a paper house, which will be rectangular in terms of, two-storey, with three doors, windows and

First of all, we recommend copying our scheme that you see in the photo in order to designate the dimensions of the future building. Then you need to decide which layout will be the length and width. Write these numbers in the diagram. Next, determine the height of the first and second floors, as well as the roofs. Now you can transfer the resulting drawing to the bottom sheet using a ruler and pencil, measuring all the parameters of the future at home. At the next stage, you need to draw windows and doors. Their location can be changed as you like, relying on your taste. The layout of the paper houses allows you to make constructive changes at any stage of the building.

At the next stage, you need to read all the "wings" that you see in the diagram. They will play the role of mounting brackets when assembling layout, maintain the roof and connect the walls. Then follows the most responsible part of the work requiring accuracy and attention. Follow all the drawing lines with a ballpoint handle over a ruler and with pressure. This is done so that you can bend paper in the right place.

Layout of paper houses require accurate fraud lines. After all the boundaries are fired, you can cut the windows and doors with scissors, as well as "wings". Next Respired Moment: It is necessary to properly bend the entire design and glue it in the right places. To do this, we recommend glue PVA. When the layout is driving, you can start coloring.

Such buildings are performed not only from paper. The layout of the house can also be made of cardboard, the material is strong enough for the structure to look "truly", with opening doors, windows, floors and ceiling, internal decoration and even inhabitants sitting inside on miniature sofas and chairs.

It all depends on how much the "builder" is interested in the final result. It can build any layout at home with his own hands. However, its execution is a complex creative process that requires accuracy and perfection. The tool will need the usual: scissors, stationery retractable knife, sewn, line (better metallic) and PVA glue.

Cardboard for making layout is better to take two types: smooth and corrugated three-layer. The second will go to the floor and the ceiling, and the first - on the manufacture of angle for connecting individual parts of the structure, small parts of the external and interior decoration. Layout of cardboard houses needed. It can be a plate glued from two layers of corrugations or carved from plywood. The basis or sole of the layout is drawn by the size of the future at home and can be made with decorative miniature flower beds, garden vases, benches.

Next, it is necessary to draw on the basis of the location of the walls, the porch and the attachments. After that, you can start making the main parts: walls with carved door and window openings, the ceiling and floor of the second floor (if it is necessary to harvest angle from thin smooth cardboard to assemble the design. The longer the corner, the stronger the connection is optimally the length of it must not be less than 70% of the length of the connection. The width of the cardboard corner is 1.5-2.0 cm.

Mock at home with your own hands from the tree can be made only with the participation of adults, as the work is associated with woodworking machines for home use. They are dangerous enough if there are no skills. Hand tool For wood processing also requires caution when working with it. The blades of knives, plans, files and pins are sharply sharpened cutting edges.

Layouts wooden houses Do with your own hands require accuracy in the process of work. Their creation is a fascinating creative occupation, in the course of which the master can show the intelligence and smelting. First you need to draw a drawing of the future at home. Then make the base for layout. After that, you can proceed to the creation of parts.

Walls and floors are better to do from thin militants with a width of 1.5-2.0 centimeters and a thickness of 5.0-7.0 mm. The blanks are located on a flat surface close to each other and fasten with the same rails that are superimposed perpendicular to top and pressed by any cargo. Previously, all parts are labeled PVA glue. After the manufactured block is dry, it can be customized according to the drawing and dock with other details.

The assembled layout must be sanded and stalled. This is done by hand the glassmaker brand 25-H on a tissue basis. Then the surface is grouped out perplex brand 8-H brand to full smoothness. After processing, the layout can be painted, install doors, insert windows and produce finishing work.

Mock at home, with your own hands created, as a rule, has a removable roof. It is necessary in order to have free access to indoor rooms, since in a miniature building will have to install toy furniture and other interior decoration items. The surface of the walls is covered with "wallpaper", i.e. the painted strips of paper. Paul must paint in brown color Or it is possible to apply it with linoleum - it can be made of loaf.

Children's crafts are not only pleasing to the eye with brightness and beauty, the process of their creation is a special pleasure for the child, because the original thing is so nice to give someone from the loved ones! And when mom joins creativity, the case argues doubly fun. If your baby has already learned to work with scissors, offer him to make a "real" paper house: templates for printing, step-by-step instruction and interesting ideas In our article.

To make a paper house, use ready-made print templates: it is much easier than to draw specifications manually. If possible, print the color pattern for the first time, it is easier to collect:

Your first paper is ready. Now you can complicate the task, selecting a black and white template for printout. Prepare brushes, paints, cardboard or watman sheets. To color a paper house on the texture, the gouache or acrylic will be best suited.

So, proceed:

In general, the design is better to think over in advance, based on the purpose of the house. If it becomes an ornament under the Christmas tree, use traditional New Year's colors - red with gold, blue with silver, white. I think of creating a whole city from paper, choose more restrained shades.

Practice shows that no matter how simple the template template is, there is always a risk to spoil the craft. Small tricks will help you avoid the incident when creating a paper house:

Having attached a little fantasy, you can expand the scope of the use of houses from paper. Here are three popular simple ideas:

Surely your baby has a lot of ideas on the use and design of houses from paper: let our printout templates will help in the realization of his creative desires.

Paper simulation can be attributed to the category of classes that will never cease to wonder the person. Many children's creativity houses necessarily organize construct mugs, because the paper models are not only allowed to get a new interesting figure or a toy - with their help you can improve the knowledge of physics and mathematics.

To learn how to add basic paper models, you will need simple devices It seems like scissors, a stationery knife, PVA and tassels for applying it. Prefers to the construction glue of PVA - from all varieties of its most thick consistency, it does not spoil the paper, making it wet and viscous as the usual one.

Different models are folded from different species Paper - from cigarette to dense cardboard. Newcomers are advised to start with watercolor paper with a density of 200 grams per m 2 for large elements and drawing paper with a density of 140-160 grams per m 2 when developing small parts.

Separate parts, like mast, railings, small finishing elements, the masters are created from polymer clay, plaster, plasticine and self-hardening plastics. If you also complement your work with stucco parts, bow to various stacks, moldes - such as those used in ceramic floristry.

The working process of creating a paper model takes place in several simple stages. Before starting the process, the master is determined which figure it wants to descriptive. In fact, from paper, you can make it possible to make practically any product, but paper modeling more often assumes such options:

Figures of man, animals, plants design much less often. After determining the category of the product, the main part of the workflow begins.

From several large and small parts fold three-dimensional patterns of paper - the diagrams of elements must be pre-draw on paper sheets the desired color. Here, a person cannot cope without understanding certain knowledge of geometry and the possibility of presenting a three-dimensional image.

To ease beginners training, many specialized magazines began to produce for a paper model drawings of finished sweeps, gluing which, you can get a figure.

Cut the layout is also needed by the rules. For example, a solid line on the contour indicates the place of the outbreak, dotted - fold. But in each designation scheme is individual, so before cutting you need to get acquainted with the explanations for the figure.

After the drawings of the paper model are ready, the layout glue and produce finishing works if necessary.

To give the surface of the product of the masters, various coatings are used: glossy varnishes, matting sprays, crackering fluids, veneers, etc.

The newcomer in paper modeling will have to taste this master class, which contains information on how to construct the well-known model of the car VAZ 21011 type sedan in just half an hour.

Fueling with dense drawing paper or a sheet with a coated coating, if the figure is created as a gift to a friend.

Please note that the strips of the testers need to be glued, forming the rings that will be attached to the wheels to get the most voluminous patterns of paper.

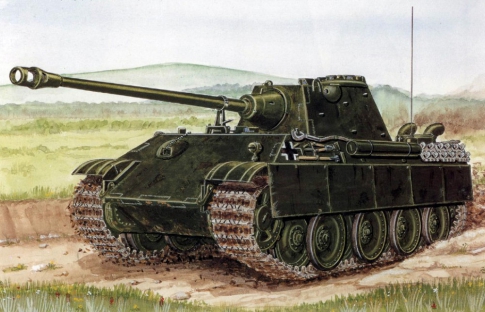

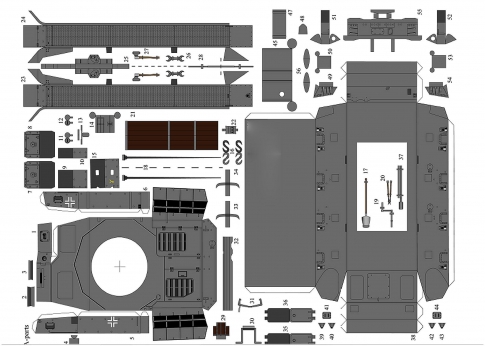

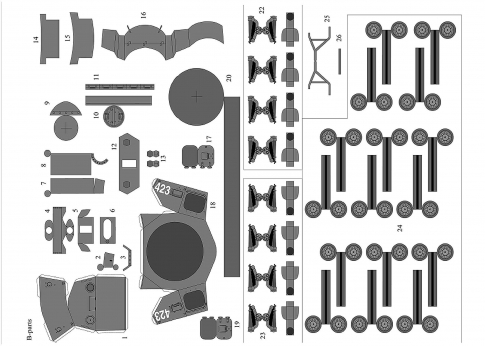

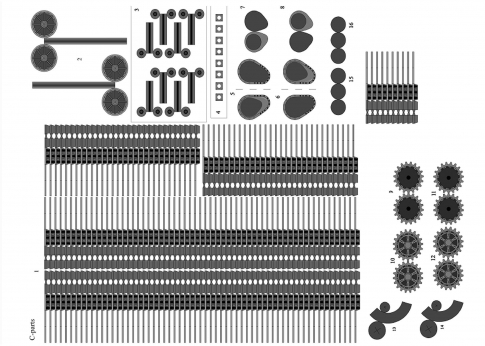

The design of military equipment from paper is somewhat more complicated than creating civil cars because the tools consist of a plurality of small parts forming the housing.

To make sure that try to form a difficult but very interesting model German tank "Panther".

To glue parts of the tank in the correct order, follow the assembly of this video language.

Sometimes jokes are connected to small errors, which is why white paper stripes appear on the model. From them you can get rid of stomers or pencils similar to color armor.

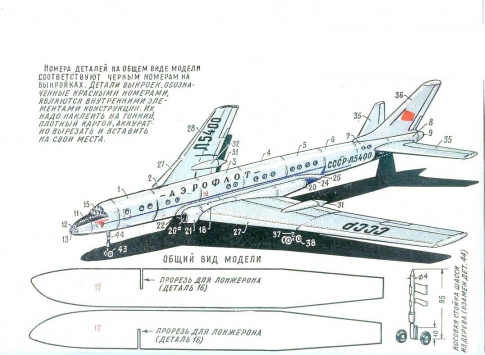

If you already have certain skills in building paper figures, you will probably like the design of the paper and cardboard of the passenger aircraft Tu-104.

To avoid bends and chances on the housing and tail, bring the parts with your cotton in the assembly process. Decorate the plane as desired using sprays and paints for decoupage.

More simple model You can make an airplane from paper to do it yourself, focusing on this video.

Take yourself, tell me friends!

Read also on our website:

show more

You will need:

White cardboard

Sequins

Rule

Latex primer (optional)

Glue stick

Scissors

Stationery knife

Decorations (tinsel, bells, balls).

1. To start, download the template This link or you yourself draw a house of similar dimensions.

2. Cut from the paper all the details and glue them to the white cardboard with a pencil adhesive or double-sided tape.

3. Cut the details from the cardboard. With the stationery knife cut the doors, windows and other details.

4. By folding the lines, fold all the elements and glue everything together.

5. If you wish, you can apply primer to the paper house so that it is not deformed.

6. Paint your house and after the paint dried, start decorating it.

The house can be hung on the Christmas tree with the help of a thread attached to the roof so that he hung smoothly, or you can simply put it on smooth surfaceso that he decorate the house.

You will need:

Thin paper (can be ordinary printed)

Scissors

Pencil

Decorations.

1. Twist each sheet (or identical pieces of sheets) into the tube. It is better to use a pencil - it is easier to twist.

2. Draw on paper or cardboard windows and door and cut out.

3. Spread the tubes with each other as shown in the image (so that the hut).

4. Stick to the windows and the door.

5. Decorate the lodge to taste.

Another option:

You will need:

Cardboard box or

Scissors

Sandpaper

Stationery knife

Tassels

Mounting foam and pistol (optional).

1. Prepare cardboard box And make a house from it. You will need to cut into the details and glue them.

2. Cut the windows and the door with a stationery knife. You can draw them in advance simple pencil.

3. Color the house or can decorate it mounting foam. To do this, apply foam strips so that each strip had a width of 1.5 cm. During drying, the foam will swell, so it is better to leave 3-4 mm between the strips.

4. After you were covered with a foam house, leave it for 30 minutes so that the foam dried.

Make a stand for a house.

From the cardboard, cut the rectangle, which must be greater than the foundation of the house.

Stick the house to the stand and decorate the stand around the perimeter of the foam.

* The use of foam is not necessary. To imitate snow, you can use the cotton wool that the pva glue.

* You can also cut out of paper or white cardboard snow slides, drifts, snowmen or christmas tree and glue them to the base, bending the lower part and apply glue on it.

If you used foam, then after drying it, cut the extra pieces of the stationery knife and treat with sandpaper.

Color all the desired details.

You will need:

Cardboard cylinders from toilet paper

White paper

Colored paper

Black felt-tip pen

Glue stick

Hot glue or plow glue

Sequins of different colors (including white).

1. Cut one cardboard cylinder from toilet paper in half, and the second and third so that you have had two long and two short parts. So you will have home different sizes.

2. Cut the white paper on the strips with a long 15 cm and 2-3 cm wide greater than the height of the cylinder, which will be wrapped in this strip.

3. Cut the windows and doors from the colored paper. Use a felt-tip pen to draw handle doors, and details of the windows.

4. With the help of glue-pencil, glue the windows and doors to white stripes.

5. Wrap the corresponding cylinders with strips and secure them with glue. Bend extra piece of paper inside the cylinder.

6. From color paper Make several cones of different colors, glue the ends of the cones, and the cones themselves are glued to the PVE glue to the cylinders-houses.

* You can add some glue to each roof of the house and sprinkle on it sparkles that will imitate fallen snow.

You will need:

Corrugated cardboard (Cardboard from ordinary packaging)

Stationery knife

Scissors

Rule

Pencil

White acrylic paint And brush

LED garland.

1. Prepare the cardboard and pencil. Draw on it several houses connected to each other. You can use a ruler. You will have a small village. Cut the village from the cardboard.

2. Bend the cut part of the harmonica on the lines, which connect at home. To make smooth bends Put a ruler on the fold line and bend the cardboard.

3. Draw on cardboard and cut the Christmas tree. Circling the Christmas tree on another piece of cardboard and cut out the second Christmas tree. Make an incision on one Christmas tree from above to half, and on the other bottom to half and connect both parts to get a 3-D Christmas tree.

4. Apply white paint on the roofs of houses and christmas trees to imitate snow.

5. Put the village and Christmas tree on a white fabric or felt and put the LED garland nearby.

Paper or white cardboard on which you can print.

* You can draw a similar drawing and cut it.

Scissors

Stationery knife

Glue stick

Candles on batteries.

1. Print and cut the drawing of the house. Window and doors cut off the stationery knife.

2. To make the roof, cut a rectangle with a size of 15x9 cm. Bend in the middle.

3. Collect and glue the house and glue the roof to it.

* You can make several houses to get a small village.

* You can also cut a Christmas tree christmas cardboard.

4. Put a candle with batteries inside the house.

* You can decorate the lodge to taste. Use stomers, sequins with glue, cotton (snow), etc.

You will need:

Box (from flakes, macaroni, for example)

Rule

Pencil

Scissors

PVA glue

Clothespin or greasy tape (if necessary).

1. Open the box completely and spread it on the table.

2. Along the unfolded box, draw a straight line 2.5 cm below the middle.

3. Do not cut from original fold lines box to the line you are drawn (see image). White dots indicate the places where cuts need to be done.

4. Cut those parts of the box where the symbol is written.

5. Turn the box and apply glue to a small bend (see image).

6. Fold the drawing box inward and secure glue.

7. Bend the opposite narrow sides so that the roof is. Each part must be bent in half (see image).

8. The wide parties do trust so that they can be glued to that part of the roof, which was formed in paragraph 7. Cut is needed with a margin so that this reserve bend and glue.