Mostly gas boilers Low power 5-7 kW is used for heating of small country facilities or small apartments with an area of \u200b\u200bup to 50 m². But, if you decide to purchase such an aggregate, it should be noted that the amendment on the heat loss can be from 10 to 30%.

5 kW gas boiler is designed for the heating of buildings that do not have chimels. Therefore, all the well-known models of such heating devices Equipped with furnace closed type. They will not need a device for a full flue system. For the output of combustion products there will be a coaxial type tube. In most cases, it comes in a set with the boiler. Such chimney is carried out through the hole in the wall and remove into the street. Best optionIf it is located horizontally.

When choosing low-power devices, it is necessary to accurately calculate whether such a boiler can heat the existing area in sufficient amount. If the construction is poorly insulated, and the doors and windows are blurred, the performance of the device in 5 kW may not be enough.

In addition, it should be noted that the manufacturer puts the utmost power of the unit in the passport. And if the gas boiler will constantly work at the maximum of the possibility, it will quickly lead to its wear. Therefore, in this case it is important to accurately determine whether the specified productivity is enough to heat your room.

Gas boilers with a capacity of 5 kW are equipped with a standard set of necessary functions and are quite simple in circulation. They are missing modern systems Management, control and safety of work, which are equipped with many aggregates with greater performance. Also, low-power devices do not have a display, control panel and the possibility of connecting other heating systems, for example, "warm floors".

Gas boilers with a capacity of 5 kW will be qualitatively damping a house or apartment when performing certain operating conditions:

The advantages of low-power aggregates include:

Minuses of gas boilers with low performance:

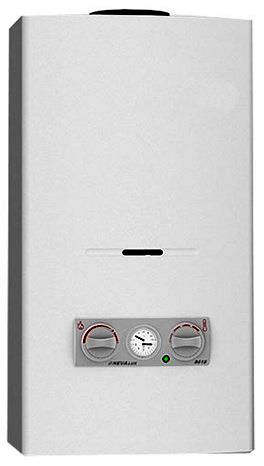

This wall-mounted parapet type gas boiler has a heat exchanger made of steel. Risel is made using electricity by pressing the button. Aggregate is equipped gas burner Italian produced POLIDORO. Safety is provided by the Gas Valve 630 Eurosit (Italy). The kit has a coaxial tube.

The boiler has the following characteristics:

The submitted single-engine model of the floor type is characterized by economy and silent work. If a failure occurs, the Italian security system "EUROSIT" blocks the supply of fuel.

The gas boiler is equipped with a set of a sectional stainless steel burner, which ensures environmental friendliness of the smoke produced and the absence of soot clusters in the combustion chamber. The aggregate heat exchanger is made of steel. The temperature of the coolant varies in the range of 40-90ºC. The kit has a chimney of a coaxial type. This boiler has no pipes for connecting to the heating system on both sides.

The gas unit has such characteristics:

Gas boilers - a fairly convenient and economical way to solve problems with heating in a private house. Most of the hosts prefer mounted 10 kW models. Such a heating device does not take up much space and allows you to warm the room with an area of \u200b\u200babout 100 square meters.

There are two main types of gas wall boilers:

When choosing a model, consider that most heating devices This class requires a chimney compound. In particular, it concerns equipment with an open combustion chamber. But recently, the leading manufacturers have begun the production of unique models with a forced burden, allowing toxic substances through a small hole in the wall. Such a development allowed the use of boilers even in apartments of high-rise buildings.

To the main advantages gas equipment For heating, there is simplication in operation. You can run it by pressing multiple buttons, and you do not need to follow it. In case of decaying the flame, the blocking system will work. But at the same time, safety rules should be observed:

Due to the fact that the majority country houses In Russian cities and towns are not equipped with central heating, the issue of housing is rather sharp. Gas heating systems easily solve the issue of creating autonomous heating. If the house is installed electric water heaterT. the best solution will be .

Today, the Russian climate technology market is overflowing with heating systems from producers from Germany, Italy, France, Slovenia and China. The domestic technology in its characteristics is not inferior to the leaders of this segment and becomes one-row with such trademarks as Bosch, Vaillant, Baxi, etc. in a huge number of models, manufacturers, trademarks are not even confused by a specialist. That is why the domestic consumer is increasingly the question arises, what gas one-connecting boiler is better?

In order to correctly pick up the model of the heating boiler, it is necessary to have an idea of \u200b\u200bthe design and the principle of operation of the device. If there are no such knowledge - then refer to the specialists. If you can imagine how single-mounted gas installations are arranged, then you pay attention to the choice of a specific model. the following points and design features:

In order to assist

Single-mounted wall boilers opens one of the most functional heating devices - Vaillant Turbotec Plus VU 122/3-5. This multifunctional installation is designed for heating rooms of a small area, up to 120 m 2. The rated power of the 12 kW boiler, which is automatically adjustable using the modulated burner. The device is equipped with a closed heat chamber, a turbine for the forced removal of spent gases, built-in multi-stage pump, which drives the coolant, copper heat exchanger, electronic ignition unit and control all installation functions, information about which is displayed on an informative LCD monitor.

Single-mounted wall boilers opens one of the most functional heating devices - Vaillant Turbotec Plus VU 122/3-5. This multifunctional installation is designed for heating rooms of a small area, up to 120 m 2. The rated power of the 12 kW boiler, which is automatically adjustable using the modulated burner. The device is equipped with a closed heat chamber, a turbine for the forced removal of spent gases, built-in multi-stage pump, which drives the coolant, copper heat exchanger, electronic ignition unit and control all installation functions, information about which is displayed on an informative LCD monitor.

This model is adapted to operation in power grids with voltage drops, thanks to the built-in stabilizer. The boiler does not work without losing power under reduced pressure in the gas highway. To collaborate with the water heater, Vaillant Turbotec is equipped with the necessary connectors. KPD - 91%. The average cost in Russian stores - 50 thousand rubles. Disadvantages - high cost.

This popular wall location model is equipped with a closed combustion chamber, turbocharging and a coercive smoke removal system. Flame modulation in the burner allows you to change thermal power in the range from 9.3 to 24 kW. Maximum thermal load of 25.8 kW. The heat exchanger material is copper. The boiler unit is equipped with a water pump, for the forced movement of the heat carrier on the heating system. The 6-liter expansion tank allows you to compensate for the extension of the coolant due to its heating.

This popular wall location model is equipped with a closed combustion chamber, turbocharging and a coercive smoke removal system. Flame modulation in the burner allows you to change thermal power in the range from 9.3 to 24 kW. Maximum thermal load of 25.8 kW. The heat exchanger material is copper. The boiler unit is equipped with a water pump, for the forced movement of the heat carrier on the heating system. The 6-liter expansion tank allows you to compensate for the extension of the coolant due to its heating.

For comfortable use, the installation is equipped with an indication of modes, auto-shirt, built-in thermometer. Safety is carried out by protecting the heat exchanger from overheating, undermining valve, gas control system. Installation has the function of automatic self-diagnosis. CPD device 92.9%. The average cost - 32 thousand 800 rubles. Disadvantages: Some models included malfunctions with a gas valve.

According to our experts and on the basis of the price - quality - functionality, the best single-mounted wall-mounted boiler from European manufacturers is Baxi Fourtech 1.24 F

This model is a single-mounted heating boiler with minor dimensions from the Russian manufacturer "Gapazparat". The maximum power of the device is 18 kW. According to the manufacturer's application, it is enough for heating an apartment or a small private house, an area of \u200b\u200bup to 180 m 2. The boiler is equipped with an open combustion chamber, so requires a separate chimney and good ventilation indoors where installed. Almost silent work of this mini-boiler is due to the use of atmospheric burner. Thanks to the use copper heat exchangerThe manufacturer of the CPD is at 90%. Gas consumption 2.13 m 3 / h. When switching to liquefied gas, Consumption is 1.59 kg / h.

This model is a single-mounted heating boiler with minor dimensions from the Russian manufacturer "Gapazparat". The maximum power of the device is 18 kW. According to the manufacturer's application, it is enough for heating an apartment or a small private house, an area of \u200b\u200bup to 180 m 2. The boiler is equipped with an open combustion chamber, so requires a separate chimney and good ventilation indoors where installed. Almost silent work of this mini-boiler is due to the use of atmospheric burner. Thanks to the use copper heat exchangerThe manufacturer of the CPD is at 90%. Gas consumption 2.13 m 3 / h. When switching to liquefied gas, Consumption is 1.59 kg / h.

Comfortable use of this boiler unit is due to the presence of car insurance, temperature and pressure in the system are displayed on the front installation panel. Safety is carried out thanks to the gas control system, the fuse valve on the water circuit and protection against the overheating of the heat exchanger. A feature of this model is low fuel consumption and ergonomic design. It is possible to connect: boiler indirect heating; Warm floor systems; air turbine; external thermostat. The average price is 20 thousand rubles. Disadvantages: often turn on and disconnected without an external thermostat.

This model is designed for consumer heating in multi-storey buildings and private houses, with an area of \u200b\u200bup to 300 m 2. The installation is equipped with a closed fuel chamber and has a capacity of 30 kW. The removal of exhaust gases is forced, with the possibility of using a separate and coaxial chimney.

This model is designed for consumer heating in multi-storey buildings and private houses, with an area of \u200b\u200bup to 300 m 2. The installation is equipped with a closed fuel chamber and has a capacity of 30 kW. The removal of exhaust gases is forced, with the possibility of using a separate and coaxial chimney.

The feature of this device is: continuous combustion modulation; the presence of 1 copper heat exchanger, not subject to low-temperature oxidation; Automatic ralizig with flame level control. It is possible to connect a water heater and transition to liquefied gas. The main advantage of the boiler unit is precise maintenance of temperature and the possibility of using a coolant based on propylene glycol. Consumers positively evaluate this heating boiler for stable operation at low fuel pressure and voltage drops. Efficiency at 100% power - 92.5%. Cost - 36 thousand rubles.

If you decide to support the domestic manufacturer and wondered what a single-mounted heating boiler is better, then according to our experts and in terms of price - quality - functionality, the best single-mounted wall-mounted boiler from the Russian manufacturer is the model NEVA-8230-1

As noted above, in the last decade, most of our compatriots prefer life from the city in own homes and cottages. Unfortunately, limited in power, so they are not always appropriate to apply large private houses for heating. In this case, outdoor heating systems come to the rescue. Further, the ranking of gas floor boilers from Russian and European manufacturers will be presented.

It is an outdoor heating system, with an atmospheric burner and an open fuel chamber. The maximum power of the boiler unit is 44.5 kW. The design of this mini-boiler includes a built-in boiler for 110 liters. for creating gVS systems in the House. A feature of the boiler is the use of a manufacturer of reliable and durable cast iron heat exchanger. According to the manufacturer's statements, its service life reaches 20 years. Main advantages: Small fuel consumption 5.2 m 3 / h; IP 40 protection class; KPD 92%. Disadvantages: does not work in low pressure gasodes. Cost - 70 thousand rubles.

It is an outdoor heating system, with an atmospheric burner and an open fuel chamber. The maximum power of the boiler unit is 44.5 kW. The design of this mini-boiler includes a built-in boiler for 110 liters. for creating gVS systems in the House. A feature of the boiler is the use of a manufacturer of reliable and durable cast iron heat exchanger. According to the manufacturer's statements, its service life reaches 20 years. Main advantages: Small fuel consumption 5.2 m 3 / h; IP 40 protection class; KPD 92%. Disadvantages: does not work in low pressure gasodes. Cost - 70 thousand rubles.

Designed for heating a small private house or cottage, a total area of \u200b\u200bup to 120 m 2. Equipped with a single-stage atmospheric burner, a cast-iron heat exchanger, electronic ignition and a flame level control sensor. The feature of this model is the design of the burner with ceramic rods and a fuel consumption regulator. The open camera and the lack of superior makes it impossible to install it in a room, not equipped with ventilation and smoke removal system with natural burden.

Designed for heating a small private house or cottage, a total area of \u200b\u200bup to 120 m 2. Equipped with a single-stage atmospheric burner, a cast-iron heat exchanger, electronic ignition and a flame level control sensor. The feature of this model is the design of the burner with ceramic rods and a fuel consumption regulator. The open camera and the lack of superior makes it impossible to install it in a room, not equipped with ventilation and smoke removal system with natural burden.

The advantages of this heating system: High efficiency - 94%; the ability to connect an indirect heating boiler; The presence of automatic self-diagnosis. The average cost of 7 thousand cu Disadvantage: Included Supplies No VRC 420S regulators.

Lemax Premium 20 is a single-circuit non-volatile russian boiler, with a capacity of 20 kW. The installation is equipped with a steel housing, a thickness of 2 mm, atmospheric burner and an open fuel chamber. A feature of this device is the innovative design of the heat exchanger, with protection against overheating and covered with a special enamel preventing it from corrosion. The advantages of this device: the presence of the air flow regulator, the functions of self-diagnosis. KPD - 90%. The average cost is 21 thousand rubles. Disadvantages: frequent problems with ignition, common flaws.

Conclusion: according to the price - quality - functionality, unanimously the best floor boilers recognized by Vaillant Atmovit Int 164-564 / 1-5.

Are you going to buy an effective gas boiler capable of providing warmth in the most severe frosts? When choosing equipment for the house, you have to take into account the set of factors. What is the best option? What criteria are the most important? Over the solution of this task, it is necessary to conceive owners and private houses, and apartments.

Agree, it's a shame to twice and eventually get a not enough functional boiler that is not able to warm vacation home With the onset of cold weather. Therefore, before choosing a gas boiler in the store, you have to weigh all the "pros and cons". Otherwise, you can take a far from a suitable model.

We will help you to determine the basic criteria that radically affect the choice. Useful recommendations I. important nuances set forth in our article. To help the homeowner, photographic materials and a selection of video materials with the advice of experienced experts in the field of heat supply are given.

The absence or permanent interruption of centralized heating and hot water supply forced the owners of cottages and urban apartments to create.

Their main element is the boiler, which, by burning fuel, heats the coolant for the heating system and water for household needs.

The choice in favor of gas equipment is due to the efficiency of use as a fuel of gas. All other options for combustible fuel are more expensive or give fewer heat.

Plus, modern heaters of this species do not require constant supervision. I connected the installation to the trunk tube or cylinder, and it is uninterrupted, while there is something to burn.

The use of natural gas is optimal on fuel costs and maintenance costs for maintenance of a private home heating

However, that the gas boiler function properly and in optimal mode, it is necessary to correctly select it when you purchase and regularly maintain after the connection.

There is a mass of differing in functionality and special modules inside models of this equipment. It should be approached to the acquisition of the heating unit on gas.

Criteria for choosing a gas boiler a lot, but the main ones are:

All these questions are closely related to each other. Lack of space for a large aggregate or desire to mount in the kitchen The device with aesthetic appearance is forced to choose a wall model of less power than rather than outdoor option. And the need for heating hot water For a washbasin and soul makes you look for a boiler with two contours.

When choosing a heater, it should be remembered about the need to repair if the workshop for service There is no choice of the model nearby, it is worth searching for another option.

Modern thermal equipment has stylish appearance, filled with all sorts of sensors and can work in several modes.

Each gas boiler has an inside the body burner and a combustion chamber with a heat exchanger, but there are models with a circulating pump and other modules

First, gas in the burner is burned with an electronic system or piezoelectric element. Then, as a result of its combustion in the furnace through a heat exchanger, water is heated, which is sent to the contour of the heating system.

So work classic single-mounted models. To prepare hot sanitary water, you need to choose either connect the boiler.

Gallery of images

Design.

For the manufacture of heat exchanger of the boiler, manufacturers use two cast iron materials and steel. Each material has its advantages: cast iron is high corrosion resistance and durability, which means longevity, steel is less weight. With a heat exchanger, a decisive role is played by design or recommendations for use.

Condensate has the greatest destructive effect on the steel boiler - if the manufacturer does not use special structural elements to reduce condensate formation (some manufacturers limit the minimum feed temperature - at least 60 ° C). The burners in design are of different execution. Now in the West, they produce mainly burners with low emissions of harmful substances, most manufacturers adapt their burners for sustainable work under reduced gas pressure in Russia.

The main advantage for low pressure Gas is a design with a submersion of secondary air already directly in the combustion chamber. This design eliminates the possible path of distributing pipes and the outlet of the burner. Basic automation. In modern heating installation, manual mode is inconspicuous, irrelevant, uneconomical.

During the service life of the boiler - and this is not one or two years - gas can be thrown into the pipe in several tens times more than the cost of automation. In addition, today it is necessary to think about the fact that every year the gas will be expensive. It is necessary to convince people that while they will feel warming with their senses, there will be a lot of cubic meters of gas. It is important to know that even a room thermostat worth about 15 euros gives up to 40% of fuel economy for the heating season, with the proper operation of the installation.

These 15 euros will be "burned" in a few months. Speaking about the cost of automation, it is necessary to admit that sometimes it is comparable to the cost of the boiler, there are cases when automation costs about 800 euros are purchased for a boiler 800 euros - but this is only a matter of expediency. In any case, the consumer has the opportunity to choose automation, it all depends on its requests. If the client has an extensive heating system, the cost of this automation will simply "dissolve" in the cost of all equipment. Probably, it is worth talking about savings over the years, rather than on unite costs.

Power boiler.

According to statistics, MGSU, who explored this question, no more than seven days after the heating season in the region costs the minimum temperature, the whole rest of the boiler turns out to be unfathomed. The underload leads to constant inclusion-shutdowns of the boiler burner (tact), and the more the boards at the boiler, the lower the efficiency and more wear of the components.

You can deal with this, increasing the number of boiler power steps. Most of the heating season, the boiler may (and should) work at 50% of power, i.e. At the first stage, do not go out. This simplifies the operation of the boiler, extends the service life of the components, slightly increases the efficiency. That is why Ideal is the reserve for the capacity of the boiler over heat loss for no more than 10-15%.

Another error is the summation of the power to heating and the DHW. Modern heating machinesUsing capacitive water heaters work on the principle of priority on the DHW: When the boiler is cooled, all the power of the boiler switches to the heating of the boiler, the heating stops, so it is not necessary to summarize the power, and it is necessary to add the estimated range of the average daily load on the cost of DHW.

Life time.

European manufacturers prescribe service life, as a rule, 10 years - on demand russian legislation. The final decision on how long the boiler can be operated, should take an operating organization. The service life is determined by time, after which the product may not execute the claimed consumer functions and its repair may be inappropriate.

In this case, it may turn out that the new boiler to buy is more intelligent. The boiler can be replaced by other reasons, for example, for reasons of economy. Today, moral aging comes to the fore, very often the boilers are replaced precisely for this reason. Knowing 100% that equipment will be replaced after 10 years, many manufacturers go along the way of savings. This is a global trend with which you will not argue.

Condensation boilers technology.

Condensation technology in our country only begins to develop. As long as they have not gained popularity due to low energy carriers, as well as with a higher cost of equipment, a small prevalence low-temperature systems heating, which allow you to get an increased efficiency of the boiler, and the lack of standards for draining in sewage network Condensate from boilers, which is essentially acid (more precisely, condensate before draining into the sewer must be neutralized by a special composition).

Condensation boilers for Russia is the technology of the future. Perhaps in the near, two-, three-year period, it will become relevant. But truly relevant will become only when the price of gas comes with the current European price.

BAXI GROUP company presents a series of outdoor cast iron gas boilers Slim with atmospheric burner on the Russian market. These boilers are manufactured at Baxi S.P.A., which is part of the holding. SLIM is 10 models with an open combustion chamber with a capacity of 15 to 62 kW, and five models with a closed combustion chamber with a capacity of 23 and 30 kW. There are both single-circuit and double-circuit boilers - with a built-in stainless steel boiler for hot water with a capacity of 50 and 60 liters.

In the models of SLIM boilers with marking "IN" there are no built-in expansion tank and circulation pump, which provide greater flexibility when choosing equipment for a specific heating system. Outdoor boilers of the SLIM series as well as all BAXI boilers are steadily operating under reduced gas pressure, producing 50% of thermal power at 5 mbar.

The SLIM series boilers have all the necessary controls, security devices and are made in modern design. Completed to the 62 kW boiler boiler model, the gas pressure switch is supplied, the purpose of which is to output the boiler in standby mode and when resuming gas supply to automatically turn it on. With permanent gas supply interruptions, especially in winterThis device is very useful and can be purchased for other Slim series boilers. In addition, SLIM boilers have an improved design and a number of fundamental advantages:

You can connect the thermostat, mechanical or programmable as accessories to the SLIM boiler, while providing the creation of a comfortable microclimate indoor. And by purchasing a device for a low-temperature circuit, you can provide the boiler at the same time on the radiators of the heating system and on the warm floors, for example, in the bathroom.

Slim boilers can be connected to Slim UB / UB INOX boilers with a capacity of 80 or 120 liters with an enameled or stainless steel tank. The temperature control in the boiler is carried out either from the boiler panel or from the boiler panel. The boiler is made in a single design with the boiler, and when they are collapsed, it forms an aesthetically finished heating unit.

In dualketurture boilers Slim. There is an antibacterial protection system "Antilegionella", which is activated once a week, heating water in the boiler to a temperature above 60 ° C. This ensures the environmental safety of the consumer hot water supply. The big advantage is the ability to combine the SLIM boilers in the cascade to create a mini spot.

With the help of a cascade control unit (RVK 22.4), you can combine up to four boilers, thus providing almost 250 kW of power. The cascade control unit provides uniform boot boilers and a stepped increase in thermal power. The boilers in this embodiment operate on an independent ring and the flow temperature is controlled by the sensor connected to RVK 22.4.

In the category of gas boilers with atmospheric torch up to 100 kW Dedietrich offers DTG boilers line. One of the main advantages of the Dedietrich boilers is a cast-iron sectional heat exchanger manufactured on its own foundry on the border of France and Germany (Alsace) for more than 100 years.

Eutectic cast iron Dedietrich is extremely resistant to corrosion, 30% plastic than standard gray and withstands large temperature differences (up to 40 ° C). The DTG series boilers are designed to work on natural gas or propane (an additional kit for re-equipment). Stainless steel atmospheric burners provide low emissions by harmful substances.

For burners there are special nozzles for stable operation at a gas pressure of 13 mbar. The DTG boilers line presented three ELITEC DTG 130 series, Dietrigaz DTG S110K and DTG 220. DTG S110K model from 13 to 48 kW - simple design, minimum electronics and, as a result, attractive price. Everything is present in the boiler necessary elements security.

To expand the possibilities of automation, there are various modules that allow you to control the operation of the boiler and adjust the room temperature. This year, DTG S110 K Dedietrich offers a new, more advanced DTGX model. The boilers of this series have retained all the advantages of the DTG S110K model and differ not only by the new design, but also the presence of a burner with an electronic ignition, the possibility of operation at a gas pressure of 10-13 mbar and various additional equipment.

The capacity of boilers increased and the range of boilers - from 23 to 54 kW. ELITEC DTG 130 - high-performance cast iron boilers of a new generation with a capacity of 18 to 48 kW. They perfectly meet the existing requirements for energy saving and environmental protection, combine modern design, ease of installation, start-up and operation.

The heat exchanger of the boiler has a special design, with an increased surface of the heat exchange, allowing it better to transmit heat and providing a high efficiency. For boilers in this series, three types of control panel are offered. The type of panel is specified when ordering and in the installation is embedded in the boiler housing. To meet any need for hot water supply with a boiler, a wide selection of capacitive water heaters is offered.

There are monoblock models (boiler and water heater with a capacity of 110 or 130 liters under one trim) and water heaters installed under the boiler or near it (150 l with a capacity). The inner surface of the water heater is covered with high quartz glass enamel, providing water storage in the best hygienic conditions.

To protect against corrosion, use a unique system with an active titanium anode, and not a traditional magnesium anode. The anode voltage is served from the control panel. Titanium anode does not require any maintenance During the service life. DTG 220 boilers with a capacity of 45 to 117 kW, unlike previous models, equipped with two-stage atmospheric burners with full preliminary mixing.

Presented two control panels. Panel k- simple automation with two thermostats for setting the temperature manually and controlling the operation of the two-stage burner, the installation of the expansion modules is provided; DEMATIC-M DELTA-electronic panel with a dialogue system of weather-dependent management of the operation of a two-stage burner.

DEMATIC-M Delta can control a cascade system (up to 10 boilers in the cascade), including the circuit of the boiler, the contour of DHW, mixing circuits and the contour of the pool. The presented Dedietrich dialog modules communicate with the user not using codes, but using well-written phrases. A wide selection of control panel data features provides large operating capabilities in heating and DHW systems. In addition, they are provided for collaboration with remote control devices on the telephone line and via the Internet.

Junkers offers two model ranges: Supraline and Supprastar. The Supraline power range is presented with six models from 28 to 56 kW. The boilers supplied to Russia are equipped with nozzles designed for pressure in the network 20 mbar, the packaging of each boiler includes a set of nozzles for the operation of the burner at a gas pressure of 13 mbar. In a number of regions of Russia, the gas pressure on the network is in the range from 17 to 24 mbar, in this case, the reduction of the boiler is not required.

For normal operation at a gas pressure from 10 to 17 mbar, it is necessary to use a nozzle kit on 13 mbar. The burner of the Supraline boiler is well adapted to the Russian conditions, its design does not allow the emergence of the "Square" of the flame when the pressure decreases. The heat exchanger is made of high-quality cast iron de dietrich. The maximum heated area for the most powerful model of this series of K56-8 E is about 550 m 2, or, when turned on into a cascade - up to 1000 m 2.

The most common and reliably running management system for Supraline: The SVM1 module is an automation, providing priority boiler control in combination with a regulator of the room temperature TRZ 12-2. From April 2006, new E8 controllers of the German company KROMMSCHROEDER will be supplied, which replaced all previously used Weather regulators of the TA series.

Suprastar power range is represented by nine models from 45 to 117 kW. Like Supraline boilers, they are supplied in a complete set of 20 mbar. The sets of reconfiguration at 13 mbar are offered. The two-stage burner enables stepped power control, its design complies with European nitrogen oxide emission requirements. However, the use of this burner is recommended only in places with relatively stable gas pressure.

With a strong seasonal fluctuation of gas pressure on the network, it is recommended to install Supraline. As a rule, Suprastar is boilers for houses with several independent heating circuits, warm floors, swimming pool. The TAC-M programmable panel allows you to simultaneously control the heating of the boiler and the main heating circuit. The use of other or two expansion boards MMX makes it possible to control according to one or two circuits with a mixer, respectively.

The panel is equipped with a special software control of the heating of the pool. To expand the capabilities of TAS-M, there is a PLUS2 TAS2 module that allows you to additionally control two more circuits with mixers. To create Cascades, SUPRASTAR boilers are offered models of "slave" boilers FM of different power. Connection is carried out using the BUS connecting cable.

Protherm

Series Outdoor ProTherm Boilers Posted by five models: "Bear", "Grizzly", "Bison", "Leo" and an independent electricity Cotele Protherm Tlo. Outdoor proTherm boilers Extremely simple is functionally, and therefore exceptionally reliable. They are durable and resistant both to temperature and loads and loads and to the human factor - violation of the rules of operation and negligence in circulation.

Pig-iron boilers of the Bear series include 13 models, different in power and functional equipment. The power series of the "Bear" series boilers is 20-60 kW. The heat exchanger from high-quality gray cast iron has a high heat transfer coefficient. Honeywell gas fittings, designed specifically for this series of boilers, and stainless steel burners provide a steady combustion mode with possible gas pressure drops on the network and a high degree of environmental friendliness, both for the environment and to maintain a comfortable indoor microclimate.

Adjusting the power of the boiler "Bear" two-stage. At a reduced stage of power (No. II), the boiler is steadily operating at a pressure of natural gas from 0.8 mbar and above. Maximum operating pressure of OS- 4 bar. Maximum temperature rs - 90 ° C. It is possible to attach the boiler to heat the DHW to 200 liters. DHW heating in this case will have priority before the heating function.

With its rated power, the Bear boilers provide hot water consumption from 16 to 20 l / min. The "Bear" series is equipped with all the necessary safety automatic boilers for this class. Stage Power Control Mode, Equitermic Regulation System, Condensate Education Protection, Removal Control System flue gases- In stock All that distinguishes a high-end boiler, but for a reasonable price.

The "Bear" model (20-40) KLZ is a boiler with a built-in 90-liter tank for heating the WPS water with a magnesium anode. Smooth power regulation, built-in circuit pumps and DHW, two expansion tanks and electronic control with autodiagnostic function. The highest class boiler and the degree of reliability for cottages and apartment houses. The "Grizzly" boiler continues the series "Bear", but surpasses its analogue in power.

In stock Five models from 65 to 150 kW of nominal heat output. Depending on the regulators used in the control system, it is possible to work "Grizzly" in the cascade of up to 16 boilers at the same time. PROTHERM floor boilers use equitermic regulators with the possibility of collaboration in the Cascade of Siemens - Albatros RVA 43.222, RVA 63.242 and RVA 63.280.

These regulators allow you to plan a weekly boiler installation cycle with the creation of time ranges and comfortable temperature modes For each range separately. "Bear", the most famous outdoor coiler Protherm, has become the basis for creating a non-electrical boiler TLOC with a nominal heat-producing from 20 to 50 kW.

Ignition of the boiler TLOProduce with a special thermoelement producing necessary for work and management electrical voltage. Gas fittings for this model developed by Sit Nova, the burner - POLIDORO. The technical equipment and functionality of the models of the rest of the rest coincides with the parameters of the "Bear" of KLO (PLO).

In 2005, the boiler TL new design. This is due to its unification in one row with the models of PLO. This eliminates possible problems with the supply of spare parts separately for a particular model. Another gallery from Protherm - "Leo" with smooth power regulation in the range from 6 to 26 kW. This is a series of condensation boilers with a built-in boiler to heat the WVS water.

The peculiarity of the boiler in its high degree of economy achieved due to the maximum possible use of the heat of flue gases and the water vapor contained in them. The maximum temperature of the flue gases at the output of 87 ° C. The boiler is equipped with all the functions of maintaining a comfortable mode, necessary defenders and continuous autodiagnostic system. The "Lev" boiler has a digital display.

Viessmann.

The company Viessmann in the floor gas boiler sector up to 100 kW offers a wide range of heating equipment, which traditionally distinguishes the highest quality, efficiency and environmental friendliness. In the sector of the updated line of boilers, you can call Vitola, Vitogas, Vitoplex. New boilers are distinguished by a more developed modular laying strategy, in particular, with regard to control units.

Thanks to the modular approach, the company managed, firstly, significantly reduce the cost of equipment, secondly, to facilitate its partners. Viessmann pays great attention to the development and support of a large network of regional service centers, And the unified approach to new management systems simplifies the repair of equipment - the service company is now enough to have only a small set of electronic circuit boards.

The body of the boiler remains almost the same, a slightly changed water filter and the weight - the boiler has become easier, it is more convenient to transport it and the load on the overlapping of roof boiler rooms is reduced. For a new modification of Vitorond boilers, a new controller has appeared, a slightly changed the design of the generator itself, due to the principle of unification, the cost of this boiler has decreased.

The line of household floor boilers of the Vitogas series has become more compact, the capacity range has slightly expanded - from 29 to 60 kW (used to be from 35 kW). Well, of course, new controllers appeared - Vitotronic 100/200 series Type KC-3, KC-4, KW-4, KW-5. A little changed design: the front wall has a more rigorous design of the trim (there is no decor on the boiler lining).

New boilers of the Vitogas series can be distinguished from the old series of labeling: before the modification was called Vitogas 050gs0, now the letter "A" appeared. Burner B. outdoor bolery Vitogas series atmospheric, partially pre-mixing, now in the upper part there are special rods - the RENOX system, due to which the emissions of harmful substances have become even lower than before.

The Renox system was patented by Viessmann in 1986. The new boilers of the Vitola series also changed the design, it primarily concerns the burner, burner casing; New KC-4, KW-4, KW-5 controllers appeared, more versatile and compact. All Viessmann heat generators have become easier, the water change has changed.

Boilers Viessmann. Designed with a significant reserve. As for the modification of the Vitoplex 100 PV1 series boiler, here the company has changed dramatically. Previously, the company offered the Vitoplex boilers lineup in two versions: there were boilers that belonged to a group of 100 SX / PX and 300TX (300 is "High Tech", the most protected from operation errors, 100 SX / PX is the most affordable model for the price, with a fairly wide range of power - from 80 to 1750 kW); But there was no meaning of the average. Now the company produces the boilers of the Vitoplex series in three variations: 100 PV1, 200 SX2 and 300 TX models - any customer request can be satisfied.

Vitoplex 100 PV1 is offered with a capacity from 110 to 620 kW. Vitoplex 200 SX2 is offered with a capacity of 90 to 560 kW. This is a classic three-way boiler with a high average annual efficiency, up to 94%, and this saves up to 25% of the fuel (in comparison with the boilers of outdated design)!

The model has low emissions of harmful substances due to the reduced heat intensity of the boiler firebox, and this is a big plus when installing equipment within the city. For this boiler also does not require a pumping circuit pump and does not need a mixing pump, because The boiler has no restrictions on the return highway.

This became possible thanks to a special design and a special start-up scheme of Therm-Control, patented by Viessmann in 1991 (previously the TRA / TSA scheme). Thermcontrol is a platinum resistance thermometer, mounted into the body of a boiler unit for registering the temperature of a mixture of hot boiler water and cold water reverse highway.

The crucial advantage is that the cold water temperature of the reverse flow is recorded inside the heat generator, and not only on the supply pipe, as in standard boilers, where the condensate is possible due to the cooling of the convective heating surfaces. Accordingly, using this boiler model, the customer saves money on such equipment as pumps, electricity and maintenance.

This model also allows operating both in the constant mode and in a variable temperature of the feed line. Viessmann offers new ranges of the 100 and series 200 series boilers, the previous line 100 is removed from production. New models of the Vitoplex 100 series - a compact solution, two-way, because both cottages and industrial enterprises There are different temperatures in different temperatures, it is necessary that it changes in the system depending on the outdoor temperature.

In fact, the control capabilities are practically limitless viessmann controllers installed in the boiler room can control the maximum 98 heating circuits with mixers and maintain up to 33 DHW systems. In addition, the adaptation concerns the DHW system. The burner devices in the Viessmann boilers can be disconnected in the summer / transition period earlier than the temperature in the capacitive water heater of the desired value is reached, and "DOGEV" to the desired value is carried out due to the heat inertia of the boiler itself!

Of course, the purpose of all these opportunities is to save fuel! And this is not a complete list of unique features. The company VIESSMANN offers a remote control and impact of Vitodata- to control over the Internet. To connect this service, it is necessary only to buy equipment, and the company itself access to the Vitodata system organizes for free.

The model of the VitoPlex 100 series implies operation at a constant temperature, equipped with a modern controller, which is also assembled according to the modular principle, the model is quite attractive at cost and very compact. Released with a capacity from 110 to 620 kW. Viessmann boilers can be combined into a cascade to four boilers, even from 11 kW boilers, you can "do such a focus".

Warranty period - 20 years, Standard warranty - two years. VIEESSMANN presenting the supply program in this range can not be not to tell about the outdoor condensate boiler Vitodens 333. The compact boiler Vitodens 333 combines the advantages of the Vitodens 300 condensate boiler and the high-quality 86-liter drinking water storage.

Its dimensions correspond to standard dimensions Kitchens and allow you to integrate the boiler in the residential area. Due to the height not exceeding 140 cm, Vitodens 333 is perfect for embedding in the roof scap or in niches. Matrix-Compact IR burner guarantees environmentally friendly operation with a minimum amount of harmful emissions.

In combination with a heat exchanger of high quality steel and a drinking water drive, the boiler guarantees the preparation of hot water with a given uniform temperature even for a large amount of water. Automatic load control ensures that heat disposal disposal during the entire loading process. All connections for electrical installation are easily accessible, the hydraulic components are pre-mounted in a single block.

Thus, Vitodens 333 allows you to install in the shortest time. The new Vitotronic controller was transferred to the upper part of the module, which not only facilitates operation, but also means certain advantages for service and maintenance.

Vaillant.

Vaillant's outdoor boilers with a capacity of 16 to 157 kW belong to the domestic sector. The company has two rules of floor gas boilers: Atmovit - from 16 to 56 kW in two versions: Single-stage Atmovit and two-stage Atmovit Exclusive; And two-stage Atmocraft - from 65 to 157 kW. All of them are certified and designed to work in networks with gas pressure from 13 to 25 mbar.

Heat exchangers of boilers - from gray cast iron. The heat exchangers for the ATMOCRAFT series boilers can be ordered both in the assembled form and in the form of a set of separate sections to assemble the boiler directly in the boiler room. Burners with ceramic rods that are needed to reduce emissions of nitrogen oxides. There are different methods for managing boilers on several steps (facilities).

Vaillant uses the control of the strokes using the throttle and change the air excess coefficient. In the same burner, with one and the same number of pipes, a different amount of gas is burned with control over the air flow. The Vaillant design has shown its effectiveness. All models of the Vaillant floor boilers are already equipped with a microprocessor control unit of the SBX-display control and preparation to control the GWS heating, which allows to significantly save when installing various additional devices.

For several years Vaillant, like other leading european manufacturers, Conducts the principles of modularity and expandability of its equipment. With the introduction of the latest group of outdoor boilers atmocraft, the company has a single automation, uniform regulatory accessories. Additional automation to control the heating system and boilers vaillant. Presented wide model near - From simple room thermostats (for example, VRT 40 worth 30 euros) to cascading weather-dependent.

The most perfect Vaillant regulatory system is a weather-dependent automation that automatically monitors the change in weather and, accordingly, adjusts the operation of the heating system. You can use two VAILLANT regulators for this purpose, embedded in boilers - VRC 410 and VRC 420 S, and you can put the same regulators into the room, then the possibility of a combination of weather-dependent and room regulation will appear.

The most complex regulator is a universal cascade VRC 630. This is an advanced device with the possibility of expansion by additional modules. Retail price of the basic configuration - 880 euros. The service life of the boilers is 10 years. Warranty period - two years from the date of commissioning, but not more than two and a half years from the date of retail.