The cast iron plant in the Polish city of Certain (Zawiercie) was founded in 1886, therefore he has more than a century-old tradition of production of cast iron products. During this time, the factory company changed several times as the owners and its name, but its products could always be distinguished by the "her" brand, which was cast along with the product. The first fittings under this brand were made at the cast iron factory in 1901.

Today, the company "Odlewnia żeliwa S.A. Grupa Gwarant, "continuing the case started by previous generations of factory workers, is constantly striving to ensure that the trademark" EE "has been identified by excellent quality, environmental safety, high business ethics and confidence.

Due to the growing competition in the market, which entailed increased demands from customers products, employees of Odlewnia żeliwa S.A. Grupa Gwarant "went through the permanent improvement of the quality management system and product implementation based on:

· Concerning attention to the fulfillment of customer requirements;

· Reducing people's participation in the production process;

· Leadership in the industry based on constant improvement of the material and technical base;

· Mutually beneficial customer relationships.

Modern environmentally friendly technologies, modernized technical equipment, qualified and experienced staff allow us to offer customers an extensive range of sanitary products, including a wide range of high-quality threaded cast iron fittings, which are a mandatory component of the pipeline of any destination.

Cast iron threaded fittings are connecting elements of pipelines made from high-quality carpet white-gray ductile cast iron - better material To ensure reliable and durable compounds. The very concept of "fitting" comes from the English word "Fitting", which is translated as "Mounting, collecting, fixed". It is clear why these connecting details It is precisely installed in places of turns, pipelines, pipe transitions to another diameter, as well as if necessary, multiple assembly and disassembly of a pipeline.

It should be noted that Polish cast iron fittings brand "It" is consistently high quality, reliability of pipeline connections and a long service life. In the systems of centralized and autonomous hot / cold water supply, as well as the supply of buildings of any destination with heat and gas, its cast iron fittings have proven itself in many years of exploitation.

Fittings for threaded cast iron "It" (black and galvanized) are manufactured a variety of configuration and installation sizes, which makes it possible to find ways to solve various tasks, both in the design process and when installing engineering communications. Pig-iron threaded fittings "It" provide the necessary strength of the pipeline at each point of the connection, reducing the risk of a malfunction to a minimum.

At the request of the installation of designers, Odlewnia żeliwa S.A. Grupa Gwarant »developed and included in the nomenclature of products a number of unique connectors - threaded black and galvanized cast iron fittings" It ", which, when installing various types of internal engineering systems Allowed to reduce the number of joints, which ultimately reduces the installation time of pipelines.

All the cast iron threaded brand fittings included in the assortment are made by the exact casting method in accordance with DIN EN 10242-1999 / A2 and ISO 49-1994, to which the floor # 1091; Chen certificate of compliance with the international standard ISO 9001-200

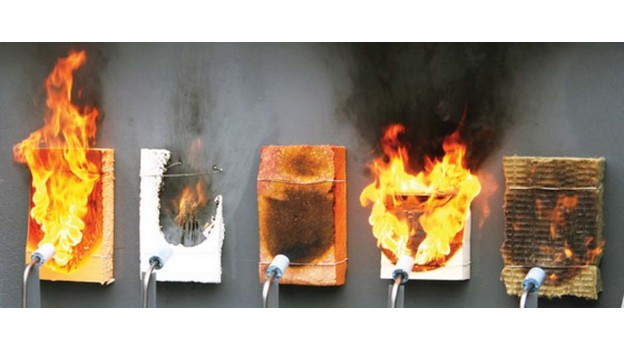

The most important quality of the material used in the construction is its combustibility. Flavoring is the property of the material to resist the effects of the flame. Therefore, five groups of flammability are defined. Four groups of combustible materials and one non-combustible. In the Federal Law No. 123, they are determined by abbreviations: G1, G2, G3, G4 and NG. Where NG is decrypted as non-combustible.

The main indicator in determining the combustion group of a particular material is the combustion time. The longer the material can be distinguished, the lower the flammability group. The burning time is not the only indicator. Also, with firing tests, the interaction of material with a flame will be assessed whether it will support combustion and to what extent.

The combustibility group is inseparable associated with other parameters of the fire resistance of the material, such as flammability, isolating toxic substances and others. All together indicators of fire resistance allow you to judge the gramifications class. That is, a combustibility group is one of the indicators of the combustion class assignment, it precedes him. Let's describe in more detail the elements of the fire resistance estimate of the material.

All substances in nature are divided into. List them:

Preferably, the use of non-combustible materials in the construction, but not all widely used construction technologies can be based on the use of products that may have such a wonderful property. More precisely, there are practically no such technologies.

To fire fighting characteristics building materials also belong:

The tendency of building materials to the combustion is denoted by the symbols of G1, G2, G3 and G4. This series begins a combustibility group of weakly combustible substances marked with a symbol of G1. A number of a group of strongly combustible G4 ends. Between them there is a group of materials of M2 and G3, which are moderately flammable and normally combustible. These materials, including the group weakly combustible G1, are mainly used in construction technologies.

The combustibility group G1 shows that this substance or material can highlight flue gases heated not higher than 135 degrees on the Celsius scale and independently, without an external fastening, are not able to burn (non-combustible substances).

For fully non-combustible building materials characteristics fire safety Not investigated and norms for them are not installed.

Of course, a group of Materials G4 also finds its use, but by virtue of a large propensity to burning, requires compliance with additional fire fighting measures. As an example of such additional measures, a floor fire cutting cut-off of steel inside the design of Ventfasada may be used if a windproof membrane with a combustibility group G4 was used, that is, combustible. In this case, the cut-off is designed to stop the flame inside the Vane gap within one floor.

The use of materials during the construction of buildings depends on the degree of fire resistance of these buildings.

Basic classification building structures The fire safety classes look like this:

To determine the materials of which flammability are permissible in the construction of a specific object, you need to know the class of fire danger of this object and the combustibility group used by building materials. The class of fire danger object is established depending on the fire hazard technological processesthat will occur in this building.

For example, for the construction of buildings of kindergartens, schools, hospitals or nursing homes, materials are allowed only by the combustibility groups of NG.

In fire-hazardous buildings with fire-resistance of the third level, low-hardened K1 and moderate K2 are not allowed to carry out the external cladding of walls and the foundation from combustible and hard-scale materials.

For non-rigorous walls and translucent partitions, materials can be used without additional fire hazard tests:

Any building facilities should not distribute hidden burning. In the walls of the walls, the places of their compound should not be present to the emptiness, which are separated from one other solid fillings from combustible materials.

Similar articles

The combustibility group is the conditional characteristic of a certain material that displays its abortion ability. With regard to drywall, it is determined by the implementation of a special combustibility test, the conditions of which are governed by GOST 3024-94. This test is also carried out with respect to others. finishing materials, but according to the results of how the material will behave on the test bench, it is assigned one of the three groups of flammability: g1, g2, g3 or g4.

All building materials are divided into two main groups: non-combustible (NG) and combustible (d). To get to non-combustible, the material must correspond to a number of requirements that are presented to it during the test. The sheet of drywall is put into the furnace heated to a temperature of about 750 ° C and kept there for 30 minutes. Throughout this time, the sample is monitored and a number of parameters are recorded. The non-combustible material should:

Plasterboard sheets in these requirements do not correspond and are therefore defined in the group G (combustible).

The combustible building materials also has its own classification and are divided into four combustibility groups: G1, G2, G3 and G4. The table below illustrates the rules to which the material must correspond to obtaining one of the four groups.

These parameters refer to the samples that have passed the tests on the MO method II test, according to GOST 3024-94. This method assumes the sample premises into the combustion chamber, in which it is affected by a flame on one side in such a way that the temperature in the furnace is in the range from 100 to 350 ° C, depending on the distance from the bottom edge of the sample.

In this case, the following characteristics occurs:

Collecting and analyzing all of the above indicators obtained in laboratory conditionsMaterial refers to a particular combustion group. Based on the numbers that were fixed when testing a sheet of GLC sizes 1000x190x12.5 mm according to the LL method described above, it was found that the combustion system of drywall - g1. According to this group, the temperature of its flue gases does not exceed 135 ° C, the degree of damage to the length of the sample is not more than 65%, damage by weight is not greater than 20%, and the time of self-combustion is zero.

See the visual process of drywall tests to combustibility in the following video:

Standard partitions on a metallic frame of plasterboard sheets of an average density of 670 kg / m³ and a thickness of 12.5 mm according to GOST 30403-96 belong to the K0 (45) fire hazard class. This means that with the fire impact on the unloaded material for 45 minutes, it was not recorded vertical or horizontal damage in it, and there was also no burning and formation of smoke.

At the same time, in practice, the carrying capacity of a single-layer septum from drywall is lost after 20 minutes of firing effect on the surface of the material. In addition, it should be borne in mind that the fire safety of a particular partition from plasterboard will depend on its design. Is it installed on metal carcass Or on a wooden crate, is there inside the insulation layer and it is combustible.

In addition to fire hazard and flammability, such characteristics as a group of combustion products, a group of smoke-forming ability and a flammability group also apply to drywall.

According to the toxicity of combustion products, the GLC sheets belong to low hazard (T1). The smoke-forming ability of the material characterizes it, as having a small smoke-forming ability (D1) with a smoke coefficient of not more than 50 m² / kg (optical density of smoke). For comparison, wood is adjusted by the value of this coefficient equal to 345 m² / kg. Flamement group at drywall B2 is moderately allegated materials.

Flavoring is the property of materials to withstand the effect of flame. This feature Important for any construction product. The combustibility group is set in accordance with the legislative parameters. Based on these norms, the building material may be non-flammable, which is indicated by the NG abbreviation, or one of the combustion groups will be assigned to it: M1 or G2, G3, G4.

The material available in combustible properties become the basis for assigning it to one of the classes.

The non-combustible materials are not lit when access to them, but their interaction with the other medium can lead to the formation of combustible products. For example, if the non-combustible material comes into contact with pure oxygen.

Empty-proof materials are capable of fire if they found themselves in the source of ignition. As soon as the effect of fire stops, the process of their burning stops.

The combustible materials have a property to ignite even without the impact of the flame, for example, with a sharp increase in temperature or at shock. The combustion of materials of this class continues, even when the source of the flame is eliminated.

Non-combustible materials belong to the combustibility group NG. However, their number is limited, and there are quite a few products with a combustibility group G2, that is, moderately burned. There are also more combustible building materials belonging to the combustible group G3 (NormallyGorious) or a combustible group of G4 (strong-brave). Their use requires compliance with additional measures. fire protection And perhaps not on all construction sites.

The combustibility group of the building material allows you to estimate the likelihood of fire. Focusing on this indicator, the category of fire danger of the room, the whole building or structure is calculated, the complex of measures to eliminate fire is determined.

The categories of non-combustible include brick, concrete, asbestos, stone Wat. They have the highest degree of fire resistance and are safe for anyone erected objects, including the buildings of social infrastructure.

Non-combustible building materials classly classify, given their ability to ignite.

Products related to group G1 are classified as weakly thorough materials. They are not able to burn outside the source of the flame. This group includes cellular polycarbonate.

Marking G2 have moderately burning building materials. The time of their independent burning outside the source of the flame should not exceed 30 seconds. PVC siding has such properties.

The group of normal-agile materials with marking G3 includes construction products that continue to burn for 300 seconds after the disappearance of the flame source. The temperature of the flue gases formed during their combustion should not exceed 450ºС.

In the strongest materials that belong to the group G4, indicators are similar to the group G3. Distinctive characteristic - The temperature of the flue gases: it exceeds the 450ºС mark. The marking of G3 and G4 has thermal insulator polystyrene foam, both foamed and extruded.

In addition to the combustion conditions, other properties of construction products are also investigated. The ability of building materials to fire allows you to classify them as a reflective, moderately ignorable or flammable. During the combustion of building materials can be released toxic substances. According to its toxicity, the product is divided into low hazard, moderately dangerous, highly hazardous and extremely dangerous. Construction products also explore the intensity of smoke formation. It can be small, moderate or high.

All these properties are indicated in the fire safety certificate and are taken into account by designers and builders.

The use of building materials on any facility may be limited to the degree of fire declared for it. The maximum requirements are imposed on the objects of social infrastructure, minimal to low-rise private buildings.

If a school is built or kindergarten, Health object, the construction refers to the Fire Resistance Class K0. Building materials laid in this project must have maximum fire resistance. To determine how class of flammability is permissible for the designated object, it is necessary to know its fire danger class.

Both Russian and foreign building materials should have confirmation of the degree and the class of their actual flammability. This characteristic is not laid by the manufacturer and is determined during laboratory tests. Test results are fixed in the appropriate laboratory conclusion.

A accredited fire laboratory has the right to issue such a conclusion. In Russia, there are several of them, and the conclusions issued by their conclusions will further use builders and designers when choosing building materials for one or another object.

The behavior of a material or system of materials under fire conditions is checked during fire tests. The more resistant to the exposure to the flame turns out to be building material, the lower the group assigned to him by the flammability.

During the home tests, various parameters are estimated, according to their results, the product receives a fire safety certificate where its properties are fixed. The validity of the received certificate is limited to several years. When the validity period of the document ends, the product must be sent to the laboratory, where its characteristics will be confirmed during the new tests.

Conducting fire tests in Russia is possible in an accredited laboratory. Such laboratories have EMERCOM of Russia, research institutes. Kucherenko.

The test of materials and construction systems occurs in a special oven. According to the test results, the protocol is drawn up. The document indicates not only the subject material, but also the Customer for these studies, as well as an organization that has fulfilled the tests.

An important parameter of materials, especially in the field of construction, is their composure. It is so priority that the flammability groups define the federal law. Four them: g1-g4. A separate discharge is allocated. It is important to understand what this classification means, it will allow specialists to choose and use building materials to ensure fire safety of objects. It is possible to determine the degree of fire consumption only in a special laboratory having official profile accreditation. Methods regulates GOST 30244-94.

If the experimental way is established that the building material with ignition loses no more than 50% of the weight with ignition, the temperature grows - no more than +50 degrees, and the flame remains no more than 50 seconds, it is determined by its non-causing and it is considered fire-resistant. If one of the criteria does not correspond to the definition, the substance is fuel, and belongs to one of four groups:

Important! In the process of testing, the following process difference is taken into account: for the first two classes, the formation of molten droplets is not expected, for three groups - from G1 to G3 is not intended to form a burning melt.

In addition to flammability classes, flammability characteristics are of great importance. They are calculated by the values \u200b\u200bof the limiting density of thermal flows. Distinguish three categories:

In addition to flammability and flammability, the fire hazard of materials is established according to the smoke-forming ability (divided by D1-D3), the possibility of spreading the flame on the surface (RP1-RP4) and the degree of toxicity of combustion products (T1-T4).

For evidence, imagine the definition of fire safety classes in the table structure.

| Execution criteria | Km 0. | Km1 | Km2 | Km3 | Km4 | Km5 |

| Burning potential | NG | G1. | G1. | Г2. | Г2. | G4 |

| Ability to ignite | — | IN 1 | IN 1 | AT 2 | AT 2 | IN 3 |

| Smoke formation | — | D1 | DZ +. | D3. | D3. | D3. |

| The degree of toxicity of burning substances | — | T1. | T2. | T3. | T3. | T4. |

| Spreading fire | — | RP1 | RP1 | RP1 | RP2 | RP4 |

When choosing building materials for a particular building or construction, their fire safety class takes into account. Moreover, this criterion must match construction, finishing, insulating and roofing products. Decoding G1 indicates that the smelting material is the smallest - the first degree, that is, this is a fire-resistant product. All building materials must have compulsory certificates confirming the group of their fire resistance. This requirement is defined by SNiP and TNPA. So combustibility G1 indicates that the use of material in construction is relevant at objects with high fire safety requirements. That is, they can be used to build the designs of ceilings, roofing and frames of partitions to which the most stringent requirements are presented.

It should be understood. In kindergartens, schools and medical institutions, claims to fireproof may be higher - only NG. Similar requirements and towards evacuation paths on any objects.

According to Wikipedia, Mineral Materials are non-combustible. This is ceramics, a natural stone, reinforced concrete, glass, brick and analogues. But if the production uses additives with another nature, then the packaging parameters are changed. Modern technologies Expand the widespread use of polymer and organic additives. Depending on the proportions of combustible and non-combustible components in the composition, the parameters of the building material can be transformed to G1, and even to the gramifications class.

To determine the substances and products in classes of G4-G1 exist special techniques. They are checked for self-burning and ignition from the source, the ability to maintain the flame is taken into account. Tests are carried out in the chamber, such parameters are defined so experimentally:

After the seizures of samples from the chamber determine the intact part, that is, the percentage of total volume, which is not charred and has not burned. Results are rounded up to 1 centimeter. Such defects like charring, swelling, chip, roughness, color changes and the calculations are not accepted. The intact part is weighed on the scales, the accuracy of which should be at least 1%. All results obtained are entered into reporting documentation, including photo report. When determining the non-compliance of product characteristics to the safety requirements at the facility, a report is drawn up.

Fire experiments can only carry out those commercial organizations that have accreditation. Example: Research Institute of Kucherenko, Ministry of Emergency Situations, Anno "Fire Audit" and others. These enterprises are required to act purely on regulatory provisions, have a complete set of equipment that has passed the calibration and specialists of proper qualifications in the state. The protocol must contain the following information:

We give the parameters of fire resistance of popular construction products:

Note! Special requirements are presented to translucent designs. For them, detailed standards are drawn up with recommendations.