Dumbbells It is very expensive. But there is a way out! They can be done do it yourself From ordinary plastic bottles in which you are used to buying mineral water or gas production!

Below is two ways to manufacture dumbbells, for girls and for men.

The first way. (For girls)

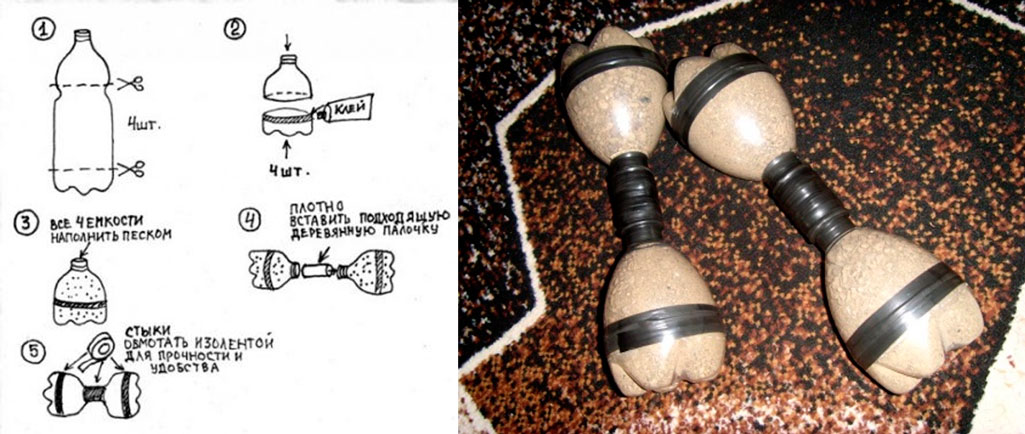

The method of manufacturing such dumbbells is simple. You need to take 2 plastic bottles, cut off in two places, cutting a few middle of the bottle (as shown in the figure, click on it to increase). Then glue two parts by a bottle with glue or scotch. In the neck pour sand or small pebbles. Then in the necks of both bottles insert a suitable plug, thereby connecting it from each other, the connection site is tightly rewinded with a tape or scotch. Such dumbbells will serve you for a very long time!

The method of the second. (For men and strong girls)

We have to:

Wooden stick. round cross section, for example, the cuttings from the shovel (you can buy in the store for 30 rubles) or a metal pipe, you can use plastic

8 plastic bottles, volume 1 - 1.5 liter, but if you want, you can take the volume and more.

So, you first need to tightly link the bottles of 4 scotch, or wire. You need to bind very tight! (as in the picture)

How to make a barbell from bottles?

You will need

Empty plastic bottles

Wide Scotch

Cutting from shovel or metal pipe

Wire aluminum

Sand or cement (other building powder)

Before you make a barbell from bottles, you need to take eight empty plastic bottles and fill them with river sand. It is best to suit the sidewged sand. During filling bottles, the sand is recommended. To make the filler put it tightly, you need to periodically beat the bottle of the bottom of the floor. You can also fill the plastic bottles of cement, but in this case the rod is harder.

Now we put the filled bottles together, but so that they do not form a row. We fasten them with a wide stationery scotch. It is necessary to make at least 30 turns so that the elements of the future rod do not hang out and are reliably fastened with each other. Now we take an aluminum wire and make a new fixation. It is necessary to fix the wire in such a way that four turns at the bottom and the neck of the bottles are formed. Thus, two bottled bundles are obtained that will replace pancakes on the rod.

In the center of each bundle there will be holes in which it is necessary to insert a stalk shovel or metal pipe. How the rod from bottles will be fixed, each invents independently. For example, you can consolidate such pancakes with a wire or a tape from both sides so that they do not move along the cutting. It will also be good for a durable cord that will consolidate the bottle bundle.

Naturally, such a rod from the subwoofers will not be able to fully compete with professional sports equipment, which is made by famous manufacturers, but a barbell rod will help to strengthen the figure in the first stages of training. To make a bar of bottles, you may need vessels from one to five liters volume. You can also make cargo of different weights, it is recommended to use bottles of different volumes. It is necessary to determine what weight should be a rod in order to correctly calculate the volumes of bottles.

It should be borne in mind that the weight of one lithon bottle, filled with sand, corresponds to load weighing two kilograms. With the help of simple mathematical computing, you can independently calculate the weight of future pancakes for the rod. Also, you need to do cargo with a lot of weight, because after a week of classes, the Stanthist will not be enough of the initial weight.

Dumbbells from plastic bottles do it easy!

You can not buy expensive simulators and dumbbells, but make them with your own plastic bottles. This will take quite a bit. The source material is practically in every home, and the work is not very difficult with which everyone will cope. The main thing as always is a desire.

So, to make Dumbbells from plastic bottles you will need some material. First of all, there will be plastic bottles. It will depend on the size of the ready-made dumbbells from plastic bottles. But usually choose two-liter bottles.

In addition to bottles, which will be the basis for creating your own dumbbells, it will also be necessary to prepare pure river or building sand, which will be used as a filler for dumbbells from bottles.

For connections structural elements Dumbbells also need a good cork, which is tightly included in the neck of the selected plastic bottles. The denser the cork gets up, the better. By the way, it can be replaced with any other suitable material, for example, a wooden wand of a suitable diameter and size.

In addition, to create your own dumbbells from plastic bottles, you need to prepare an insulating tape, good glue and scissors. Instead of scissors, you can also use a well sharpened, sharp knife.

How to make your own dumbbells from plastic bottles

Plastic bottles are prepared properly. They need to be well to wash, contemplate labels and stickers from them, and then dry thoroughly. After that, start creating blanks.

Dumbbells from plastic bottles consist of mini-bottles that are made from large bottles. To do this, you need to cut the upper part of the selected plastic bottle and its bottom. The height of the cut bottle from the top should be approximately ten or fifteen centimeters, including a plastic bottle neck.

The lower part is cut off so that there is a stock for gluing.

After that, both billets combine with each other and plant a high-quality and strong glue. To give homemade dumbbells from plastic bottles. Additional safety margin, the connection is tightly wrapped with several layers of the tape.

As a result of all these manipulations, a kind of mini plastic bottle should turn out, which is part of the future dumbbell. But to create dumbbells, you need to do two such bottles, so all the same is repeated with another plastic bottle prepared in advance.

After the workpieces are ready, they fall asleep clean river or building sand, which gives the dumbbell weight. Then both "mini-bottles" are connected using a dense traffic jam. The compound is also tightly wrapped with an insulating ribbon to give homemade dumbbells from plastic bottles more strength.

All - dumbbells from plastic bottles are ready and you can proceed directly to the exercises.

Not everyone who wants to play sports have enough time to visit the gym, and home training requires a certain inventory, the cost of which is sufficiently high. Dumbbells are most popular. They are involved almost all exercises. And if you acquire a sports equipment in the near future, it is not planned, should not be abandoned. You can make dumbbells with your own hands from rather cheap materials. To do this, it is enough to familiarize yourself with the instructions on how and what they are doing.

Conventional plastic bottles allow you to make dumbbells with minimal cash costs, to use which you can immediately use. The main thing is to fix the structural elements well so that it does not destroy during training.

For the assembly of one plastic projectile, it will take: 2 bottles, tape or insulating tape, filler.

Step-by-step instructions for the manufacture of dumbbells from plastic bottles:

Before starting classes, it is necessary to carefully check all the connections so that the filler does not "lean."

Conventional plastic bottles are suitable not only for collecting dumbbells, but also the rods. This shell weighs much more, therefore the amount of source material increases.

For the assembly of the bar, it will be necessary: \u200b\u200bat least 8 plastic bottles, neck, material for filler, tape or tape.

Instructions for the manufacture of plastic rods:

Focusing in the choice of material is quite difficult. Approximate weight Dumbbells or rods can be calculated based on the data presented:

The weight of a two-liter plastic bottle with various fillers:

Mass is given in kilograms.

Cement base allows you to get heavier dumbbells and rods than using plastic bottles. Pancakes are not only more impressive weight, but also look much more solid. They are cast from a cement mortar in a special form, inside of which is a vulture. The disadvantage of such a design is that the projectile load cannot be adjusted or adjust to anyone else.

To start working with a different weight, you will need to make a new barbell or dumbbells. Utazeliters, in fact, are obtained individually, and quite fragile and "bulk". The last drawback is eliminated by the introduction of glue into the solution. And if classes are not conducted on the principle of paeerlifting, when the projectile is thrown to the floor, then it will last for quite a long time.

The manufacture of concrete dumbbells (rod) will be required: metal pipe with the required length, bolts or screws, cement mortar, PVA, and a form for laying a cargo.

Step-by-step instructions for the manufacture of cement shells:

Shells, poured into a two-liter form, can weigh about 5 kg. The accurate weight is due to the composition of the mixture involved.

To perform a "farmer's walk", optionally do shells. Enough to take two ordinary canisters and hang on a stick. You can use tires filled with sand or any other filler. Other exercises with a similar design are difficult to perform. They require the use of full dumbbells.

When sports are becoming regular, there is a need to acquire more professional shells or make such metal. They are practically no different from factory. The difference is that the dumbbells made by their own hands will cost much cheaper. From one pipe can be simultaneously made and pan, and pancakes. Best of all of the metal do a set dumbbell.

To make shells, you need to prepare in advance: thin-walled pipehaving a diameter a little more than the griffon in which it is better to take a metal rod, lock locks and leaf steel. Works on the manufacture of dumbbells should be carried out in a plumbing workshop.

Step-by-step instruction:

The dumbbells made in the described method are not inferior in quality factory, allow you to work with small, and with great weight.

The best without any doubts are metal shells, but they are much more difficult in the manufacture, rather than other designs. It is necessary not to just make discs, but to properly choose the width of pancakes, to perform locking locks according to the calculations. It is not recommended to increase the width, but the diameter of the disks. You can make some heavy and somewhat small pancakes.

So that the dumbbells looked presentable, the details are grinding and stained. This only slightly weights the process of creating and increase the cost of shells, but they will look no worse than the factory, and the price is much smaller. Classes with such inventory will bring more fun, and, consequently, the motivation and the effect of training will increase.

You should not spend time and strength to create dumbbells weighing up to 100 kg. Instructions for the assembly of such structures on the Internet abundantly, but it is better to immediately make a barrel with the calculation of 200-300 kilos to perform a traction. Dumbbells for such loads are not suitable. And if you have a hardware, then with a serious projectile, that is, a barbell.

If such an opportunity is, you can buy a neck with a handle in the store, and pancakes either do yourself or order in the workshop. Qualitatively performed handle contributes to comfortable classes, and homemade pancakes Significantly reduce the total cost of the projectile.

For many people who want to play sports, the issue of visiting the gym is closed due to a lack of time, and its own sports equipment for households is not so cheap.

Despite the simplicity of manufacture, the site of the sporting goods is simply not interested in selling a metal slices.

Moreover, it is not a fact that every dumbbell and even the rod from the bar will suit you on the diameter and shape of the handle, material and other characteristics.

A fully adequate response to such a price policy was the manufacture of personal sports inventory by many craftsmen. For this apply different materials, Methods and designs.

Now we will consider the most common of them so that you can choose and make your own dumbbells or barbell yourself.