The ability to create furniture with your own hands can give us many benefits. A finished item with individual dimensions can perfectly fit into the room, and the correctly selected upholstery will be combined with the general interior of the room. It is also important to note that you can make a corner sofa with your own hands much cheaper than buying a ready-made version. Many home craftsmen, who managed to get their hands on ottomans and stools, easily assemble sofas with their own hands, both corner and ordinary.

The corner sofa is very useful and comfortable, as it saves a lot of free space in the apartment when assembled. Also, the sofa can hold all bedding, children's clothes, shoe boxes, toys and much more. Don't forget about prestige, because the corner sofa looks much more solid than usual.

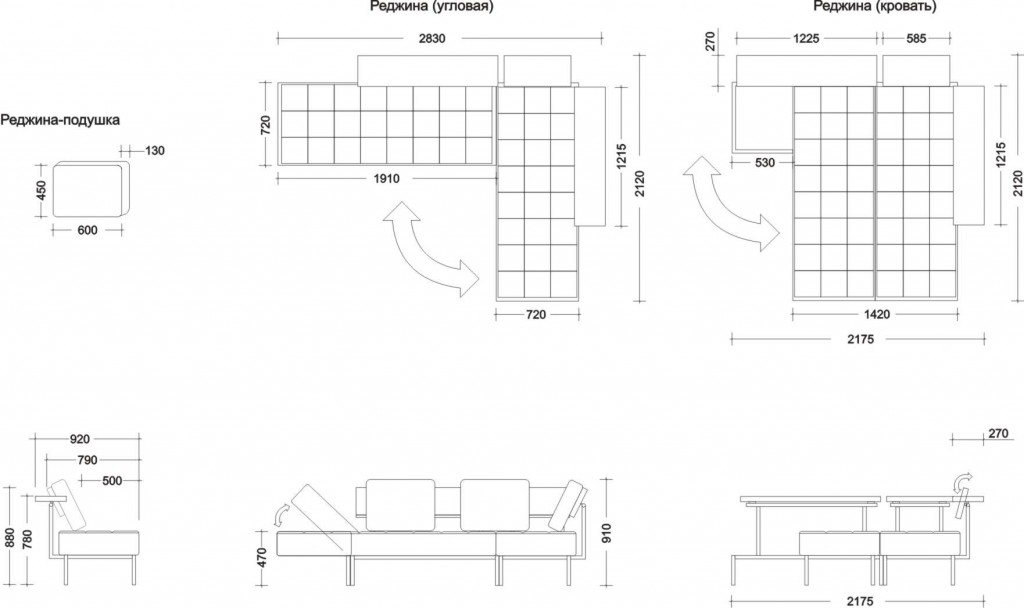

First of all, you need to decide on the design of the piece of furniture and where you will put it in your apartment or house. It is better not to consider complex designs with oval tables and shelves at first. First, try to make a corner sofa with your own hands in some simple shape.

First, make a detailed drawing of the sofa with the designation of all sizes and details. Give up expensive materials (large cross-section beams, laminated plates, etc.), and you also do not need labor-intensive finger joints, which are available only to professional carpenters.

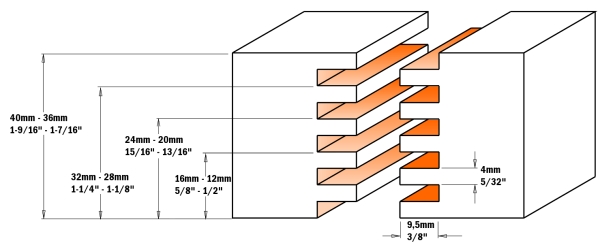

People often tend to simplify their task by fastening parts with ordinary nails. This is wrong, as they quickly loosen and the sofa begins to creak and literally fall apart. The best option is self-tapping screws. Having cut once, especially into softwood, these fasteners hold the load perfectly for a long time.

You can't do carpentry without glue. But before smearing and joining surfaces, you need to make sure the assembly is correct. When the glue, be it ordinary PVA or some other, sets, you will not be able to separate the parts. It will only be necessary to break them out and cut new ones.

It is believed that boards without lamination should be varnished in several layers to prevent the release of formaldehyde into the air. In fact, this requirement is rarely met. This is partly due to the fact that the environmental friendliness of the material has become much better. Many craftsmen limit themselves to the usual stain.

Parts cut by yourself must be sanded with fine sandpaper. The treated surface changes its properties and becomes stronger. In addition, working with smooth wood is much safer, as is the subsequent use of furniture.

To assemble a corner sofa, you will need the following materials:

To work, you need the following tools:

Before assembling a corner sofa, you should estimate how much dust and noise will be from using an electric jigsaw. If you are forced to work in a cramped city apartment, it is better to order a cut from the same organization where you will buy chipboard. Craftsmen will quickly cut the material to your size with maximum precision. In this case, you will no longer be able to adjust the dimensions during the assembly of the sofa.

Before making a corner sofa, weigh how much noise and dust there will be from the jigsaw. If you have to work in a cramped city apartment, then it is better to order sawing slabs at the same base where you will buy chipboard. Specialists will cut material according to drawings with high accuracy and with a minimum of loss. True, adjusting the size along the way will no longer be possible.

First you need to arrange the finished marked parts separately: armrests, frame, seats, backrest. Items are collected in this order:

After assembling the left part, you can consider that the process of making the corner sofa is almost complete. It is necessary to arrange the details of the right side, not forgetting that the bottom will act as a linen box. In a familiar way, fasten the longitudinal and then the transverse beams to two identical side elements.

After assembling the frame according to the drawing, sew up the bottom with plywood. Twist the back, screw the chipboard to it. After that, you need to cover the side openings with the cut plates. Sew up the back of the furniture with chipboard only if the sofa is in the middle of the room. After that, drill the holes for attaching the microlift. Use M6x30 grade bolts for fastening the lifting mechanism with furniture caps.

First you need to take the dimensions of all surfaces and cut the foam rubber along them. Having cut out the part, you need to stick it in place. At the same time, each subsequent detail will be easier for you to customize. Foam rubber with a thickness of 100 mm is suitable for seats.

If you don't find a material of this thickness, glue together from two 40mm and one 20mm. Use all trimmings when cutting suitable geometric shapes and fitting them. If you do everything carefully and without haste, you will receive a high-quality finished product to order, and in the future you can even make money on this.

First you need to make templates for all covered surfaces. To do this, cut out patterns from newspapers or wallpaper, checking the dimensions according to the drawings. We cut out the fabric according to the patterns. If this is difficult for you, simply apply the material to the seat or backrest, marking the borders with chalk. The fabric must be cut with the wrong side up. Leave seam allowances at least a centimeter, and if the edges crumble, you can.

Symmetrical recesses in the upholstery, called crimps, not only change the look of the sofa, but also hold the fabric in place, reducing the appearance of wrinkles. Holes are pre-drilled in the slabs for them. For tightening, loops are used from a strong nylon cord, pre-sewn to the upholstery.

To reduce the degree of abrasion of the foam rubber, agrotextiles are placed between it and the casing. then the upholstery fabric is shot with a stapler. You can collect all the elements into one whole.

As a result of the work done, you will receive a neat, comfortable and relatively inexpensive corner sofa that will serve you faithfully for a long time.

A detailed video tutorial on how to create a corner sofa: